A new Sabroe compressor controller is soon to be released by Johnson Controls. Boasting “ultimate connectivity”, Anders Amdi Soerensen, product manager for the company’s Refrigeration Controls Division describes the development and functions of the Unisab III

IT WAS not until the late 70s that the refrigeration industry started to take an interest in electronic controls and it was then only reluctantly that the market adopted this new technology – and with good reason.

Most hardware was proprietary and, even though some of it was well designed for industrial environments, most of it would often fail due to electromagnetic susceptibility, temperature, vibration sensitivity, etc. However, the improvements showed up fast and the big players made a break through in the late 80s/early 90s with their PLC (Programmable Logic Computer) systems to replace conventional technology.

At Sabroe, now part of Johnson Controls, the late 70s saw the introduction, albeit on a small scale, of the first PLCs for industrial applications and microprocessor-based control systems for marine applications. It was not until 1985 that the first compressor controller, designated MicroProsab, was released for screw compressors followed by an updated version Prosab II in 1988.

Development went on to include a reciprocating compressor controller Unisab I which was eventually divided into several product units. These were later combined into one single multipurpose compressor controller Unisab II released in 1995. To put things into perspective, the first MicroProsab panel had a dimension of 650mm x 1000mm x 200mm and the Unisab II panel, 10 years later, had a dimension of 200mm x 460mm x 130 mm with a performance far beyond the MicroProsab.

The importance of this product is shown by the number of Sabroe compressor controllers in the field which currently stands at about 25,000, of which 19,000 are Unisab II.

The Unisab II has been developed through the years by regular updates with features and functionality to meet and keep up with market requirements. The advantage of a versatile controller like this is that the usual compressor/chiller functions such as control loops, safety and operating limits, optimisation and sequencing are included and it can be configured to suit almost any type of industrial compressor type or refrigerant in several languages, etc. The sequencing system will optimise a mix of reciprocating and screw compressors with or without VSD. This means that very little additional equipment is needed.

To communicate with the Unisab system, a Comsab interface module is available which connects to a PLC/BAS system through a RS232 port, and to exchange data with a PC a RS2LAN Ethernet interface module is available.

To build total refrigeration plant control on top of the Unisab and compressors, Johnson Controls has the Sabvisual/YSAC system, which is a toolbox developed for fast, easy and safe design of controls applications.

It is based on a standard SCADA system, adapted to refrigeration applications through standard items (pumps, valves, etc) and modules (evaporators, pump packages, condensers, etc) organised in a menu from which items can be dragged and dropped to design an application. At the same time, functional standard blocks available for the PLC and the YSAC toolbox will generate the complete controls package, PC and PLC, for the application.

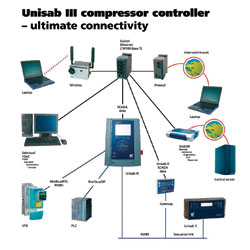

Fig 1: connectivity of the controller with several communication ports on board to eliminate gateways

Connectivity/integration

To meet the increasing market requirements for connectivity/integration of controls systems, Johnson Controls has a new chiller/compressor controller under development. Fig 1 illustrates the connectivity of the controller with several communication ports on board to eliminate gateways.

The controller will connect directly to the remote monitoring system RADAR (remote access, diagnostics and response) with the potential to log on to chiller/compressor packages from any location. The HMI (human machine interface) will be straightforward and intuitive to operate through the graphical display and a few keys to navigate in a similar menu structure as the Windows file manager.

Future considerations

Energy savings are still one of the drivers in the refrigeration business. Obviously, focus is on compressors as the biggest energy consumers and, as they often run at part-load, variable speed drives are an effective way to improve part-load performance and save energy. The new SABCube screw compressor/chiller package is a true full integration of compressor, driveline and control system to meet future requirements and set new standards.

An effective intelligent overall plant control system should link the refrigeration components together in a fully integrated package and reflect the dynamics/interactions of the components, not just to save energy but also to improve the quality of products or processes.

A floating suction setpoint in compressor control will improve cooling capacity by 3% for every degree K it can be raised and consumed power can be reduced by 3% for every degree K that condensing pressure is lowered. These values are rule of thumb, influenced by the type of application and other factors. Functions such as self tuning and adaptive control loops should be expected in future control systems.

The hardware will become much more flexible when it goes wireless; put in a sensor or actuator and assign it to a network without having to modify any wiring.

Data safety is likely to be an issue and remote access will be another driver. This has already been in progress for years but on a small scale. However, it will accelerate and open up opportunities for linking installations together on a global basis for maintenance, service, diagnostics, optimisation, tuning and statistics.

Controls have the potential to be the major enablers in energy savings, intelligent operation of plants and global remote access.

Future control systems will be based on software that can learn and adapt the process to save energy and improve the quality of the end product. Intelligent control systems, including diagnostics and statistics, could report back to a global database to develop new controls strategies that would then be downloaded to the plants.

Johnson Controls

01753 870887