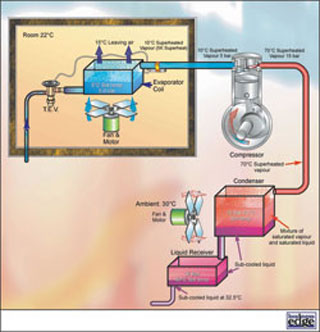

The expansion device

The refrigerant is now available as a high pressure, sub-cooled liquid for return to the evaporator coil via the expansion device. This is normally a regulating valve (TEV – thermostatic expansion valve) with a sensor attached to the external surface of the refrigerant pipe leaving the evaporator coil. The TEV regulates the flow of liquid refrigerant into the evaporator coil by maintaining a pre-set superheat value at the evaporator coil outlet. This ensures that the evaporator is adequately supplied with liquid refrigerant to meet the instantaneous cooling load and that the superheat is correctly maintained at a level which ensures the best utilisation of evaporator capacity, whilst ensuring liquid refrigerant does not return to the compressor. The TEV will be studied in greater detail later in the series.

Liquid refrigerant enters the TEV at 15bar, a saturation temperature of 40ºC and at a temperature of 32.5ºC. As the liquid refrigerant passes through the valve from the high pressure region to the low pressure region, the pressure drops top 5bar causing the saturation temperature to fall immediately to 5ºC at 5bar.

Figure 1

Flash gas

The drop in pressure forces the refrigerant to immediately drop in temperature from 32.5ºC to 5ºC and a portion of the refrigerant is vaporised (flash gas) as the remainder rejects heat energy. This is effectively a loss of refrigeration capacity since less liquid refrigerant is now available for subsequent cooling within the evaporator. The balance of liquid refrigerant remaining vaporises within the evaporator and is superheated by approximately 5-7K. The cooling effect resulting from this process is known as the net refrigerating effect. The flash gas process does not result in any change of energy since the remaining liquid has lost an equal amount of energy to that gained by the vapour produced.

The absorption refrigeration cycle

The absorption refrigeration cycle was conceived by Carl Munters, a Swedish chemist. He was also responsible for the development of the lithium chloride desiccant dehumidifier, a remarkable product with which the writer was extensively involved whist working at Rotaire Driers Ltd (now Munters Ltd) over several years. This technology will be described later in the series.

The absorption refrigeration cycle is mainly directed at air conditioning applications. There are two basic variants: single-effect and double-effect. The cycle utilises two fluids, one termed the refrigerant, the other being referred to as the absorbent. These fluids are:

Refrigerant / Absorbent

Single-effect absorption machine: ammonia / water

Double-effect absorption machine: water / lithium bromide

The presence of either ammonia or lithium bromide within a confined space occupied by people cannot be allowed from a safety viewpoint and the cooling equipment must therefore be sited outside the building to be conditioned. As it is not possible to pipe ammonia into the building, the DX split system approach cannot be employed and all absorption cycle equipment is therefore designed to chill water (water chiller) which is then piped to the conditioned space(s). The chilled water is supplied to fan coil units sited in each of the conditioned spaces. The application of this technology is therefore well suited to multiple room systems or large spaces requiring air conditioning. Absorption chillers are a well-established technology that can offer considerable advantages over conventional, mechanically driven, vapour compression chillers.

Rather than using a mechanically driven, electrically powered compressor and conventional refrigerants, the absorption cycle uses the fluid pair described above and a heat source. The refrigerant has a high affinity for the absorbent, which essentially means that the absorbent attracts the refrigerant vapour and absorbs the refrigerant. This creates an attraction, which can be likened to the suction action of a mechanical compressor in a vapour compression cycle.

The cooling cycle is driven by the heat source, which is typically a gas burner, steam or hot water. The heat source is used to boil and drive the refrigerant out of the refrigerant/absorbent mixture. This mixture is normally termed solution.

The refrigerant is then passed through a condenser to remove the latent heat of condensation, thus returning the refrigerant to liquid form. It is then passed to the evaporator where evaporation draws heat from the recirculating chilled water. The resulting vapour from the evaporator is attracted to and absorbed by the absorbent solution to complete the cycle. In effect, the mechanical compressor of a conventional vapour compression cycle has been substituted with a ‘chemical pump’ driven by heat.

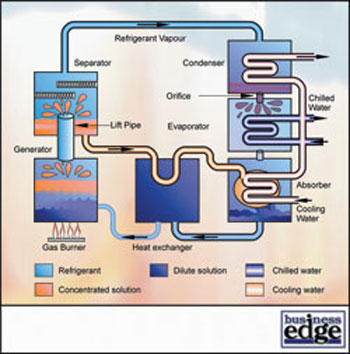

Figure 2: Single effect absorption cooling cycle

The generator

Referring to Fig 2, the refrigerant/absorbent solution in the single effect cycle is heated directly by a gas burner or by hot water or steam from a combined heat and power (CHP) system or boiler. The boiling point (saturation temperature) of the refrigerant is lower than that of the absorbent and the solution therefore separates as the refrigerant evaporates and passes to the condenser. The pure concentrated absorbent passes to the absorber vessel. The heat applied to the generator also generates the high side pressure of the system.

The condenser

The air-cooled condenser rejects heat from the refrigerant to atmosphere, causing the refrigerant to desuperheat and condense to liquid form. The liquid refrigerant then passes through an orifice having the same action as an expansion device in the vapour compression cycle, which results in a reduction in pressure and saturation temperature. The refrigerant then passes to the evaporator.

The evaporator

Water returning from all fan coil units contains heat energy from the conditioned spaces and is passed through the evaporator where the heat energy is absorbed by the refrigerant vaporising at low pressure and saturation temperature. The low-pressure refrigerant vapour is drawn to the absorber by the absorbent. The chilled water returns to the building to perform further cooling.

Figure 3: Double effect absorption cooling cycle

The absorber

The concentrated absorbent is cooled and mixed with the low-pressure refrigerant resulting in a weak solution. This weak solution is pumped back to the generator to complete the cycle.

The pump

The pump is the only moving part in the absorption cycle and is usually a diaphragm pump running on a single-phase power supply drawing very low current.

Double-effect absorption cycle

This is a variation on the single-effect cycle and has two generator stages. Heat energy is recovered from the first stage and is utilised in the second stage. Consequently, these units are more efficient than single effect units. The double-effect absorption cycle normally employs water as the refrigerant and lithium bromide as the absorbent as stated above. This cycle operates at very low pressures within the evaporator in order to produce a low saturation temperature for water.

Construction

As ammonia reacts adversely with copper and brass, the entire refrigeration circuit is constructed from steel.

Capacity range

Absorption chillers are available in the following capacity ranges:

Direct-fired absorption cycle chillers: 10 kW to 5MW Indirect-fired absorption cycle chillers: 20 kW to 5MW

Most direct fired units are able to offer an optional gas-fired heating capability.

Energy efficiency

The performance efficiency of all heating and cooling equipment can be defined by the coefficient of performance (COP). Chilling output is divided by energy input to arrive at COP. Single effect absorption chillers have a COP of approximately 0.6 and double effect units can boost this to 0.95. The COP of vapour compression chillers is often quoted between 2.5 and 3.0. However, the generation of electricity results in losses that do not occur with the burning of gas. If the generation efficiency of electricity at the power station were assumed to be 33%, the true overall COP of vapour compression chillers would fall between 0.83 and 1.0.

TEWI The total equivalent warming impact (TEWI) is a measure developed by the air conditioning and refrigeration industry to assess the total contribution to global warming emissions for a specific item of air conditioning or refrigeration equipment. These emissions include the energy consumption of the equipment throughout it’s working life and the energy efficiency of the equipment plays a major part in determining the TEWI rating for a particular item of equipment. It must be remembered that each model in every manufacturers range of electrically driven and absorption cycle products will have different efficiency levels and TEWI ratings. Other systems exist that will transfer heat energy from one part of the building to another thus attaining incredibly high COPs and very low TEWI ratings.

With thanks to Mike Creamer of Business Edge who revisits his Masterclass series of articles, updating and adding to the information which proved so useful to readers when the series was first published over ten years ago. In this reincarnation, the series will cover both air conditioning and refrigeration and serve as an on-going source of technical reference for experienced personnel as well as providing a solid educational grounding for newcomers to our industry.