It has been reported that heating homes and workspaces makes up almost a third of all UK carbon emissions. A large fraction of that comes from existing buildings stock. The UK has already made considerable progress in this aspect, recently released national statistical data shows that greenhouse gas emissions in 2020 were estimated to be 49.7% lower than they were in 1990, of which carbon dioxide made up around 79% of the total. The UK was the first major world economy to pass a net zero emissions target into law. This target requires the UK to bring all greenhouse gas emissions to net zero by 2050.

To achieve this target, heat pump, one of the best low carbon technologies currently available in the market, is expected to play a vital role in helping to decarbonise heating in buildings in the construction industry over decades to come.

Heat pump requires a small amount of electricity to run, and typically has an energy efficiency of 4. That means, for every 1 unit of electricity it consumes, the heat pump can deliver 4 units of heat energy. To put this into perspective, the efficiency of electric heaters is around 1 and the efficiency of a typical new gas boiler is about 0.8-0.9. If the power supply to the heat pump is from renewable sources, the system itself will become completely carbon neutral.

To encourage uptake of low carbon heating technologies, the UK government has set up schemes across the relevant sectors to provide grants and funding to speed up installations. This includes schemes such as Boiler Upgrade Scheme (BUS), Heat Pump Ready Programme, further funding for the Social Housing Decarbonisation Scheme and Home Upgrade Grants and so on.

The Refurbishment Project - Dartford Civic Centre

As an initiative to reduce carbon emissions in buildings, Dartford Borough Council had completed a number of refurbishment projects recently including the Dartford Civic Centre, Orchard Theatre and Sports Hall.

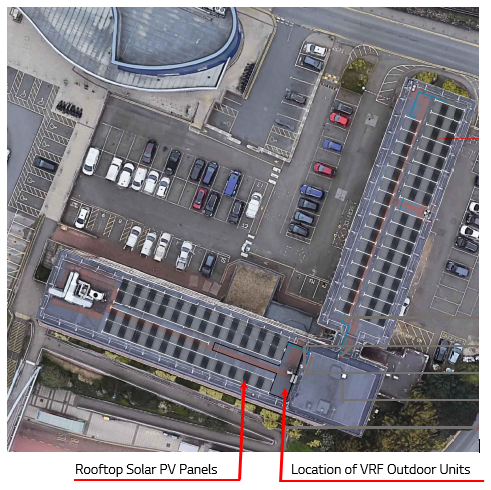

Although several CO2 reduction measures have been implemented in the Dartford Civic Centre refurbishment project, such as fitting day/night and movement sensors to the control loops of the LED lighting system, solar PV panels on the roof, this article only covers the low carbon element of using heat pumps to replace gas boilers in this building.

Although several CO2 reduction measures have been implemented in the Dartford Civic Centre refurbishment project, such as fitting day/night and movement sensors to the control loops of the LED lighting system, solar PV panels on the roof, this article only covers the low carbon element of using heat pumps to replace gas boilers in this building.

The Dartford Civic Centre is a five-story office building built in 1970s. It is an “L” shaped building situated close to Dartford railway station in Kent. It is a public building used as the council offices by the local government.

Before the refurbishment, the space heating in the building was centralised and distributed via a single pipe system with heat emitters. The heat used for the system was generated by gas boilers installed in 2017. The funding for this refurbishment project is from UK’s Public Sector Decarbonisation Scheme (PSDS). It supports the aim of reducing emissions from public sector buildings, and provides grants for public sector bodies to fund heat decarbonisation and energy efficiency measures.

The aim of this refurbishment project was to use air source heat pumps to replace existing gas boilers, in order to reduce CO2 emission from this office building. The design intention was that the new plant will be used to serve the retained existing heating system, which distributed LTHW heating to heat emitters located across the Dartford Civic Centre building throughout.

In comparison with fossil fuel boilers, the combination of VRF and hydro kits, supplying hot water for space heating in this building via the existing single pipe heating system, has the following advantages:

- Renewable heating solutions, high efficiency and low CO2 emission

- Environmentally friendly technology, no exhaust gas emission from hydro kit and therefore no air pollution to the surrounding atmosphere

The main players of the project team were:

- Dartford Borough Council Climate Change & Property Team

- Ferguson Brown Sustainable Engineering Ltd was the project design consultant

- TSG Building Services was the installation contractor

- LG Electronics was the manufacturer and supplier for the VRF systems, low temperature and high temperature hydro kits, and associated accessories

Working with the VRF manufacturer, the design consultants provided technical support for applying and securing the project funding from the funding body. In this project, the construction cycle was relatively short, and only took about six months from design to completion.

Carbon Neutral Solution

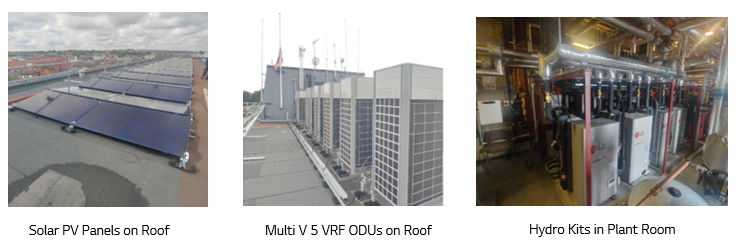

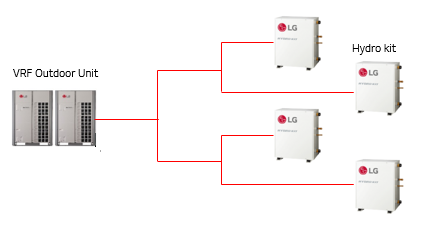

LG’s VRF and floor standing hydro kits were selected to provide the low carbon heating solutions to replace the existing gas boilers for this building. The centralised heating system was comprised of four VRF systems with a total of 16 hydro kits:

- System 1 and 2 were identical with high temperature hydro kit models, generating hot water with leaving temperature up to 80°C

- System 3 and 4 were identical with low temperature hydro kit models, generating hot water with leaving temperature up to 50°C

- The two different temperature water supplies were mixed to generate a water temperature of about 65°C, which was then connected to the retained and reused existing single pipe heating system via plate heat exchangers

- In order to use cost-effective off-peak electricity during night-time, two large thermal store buffer vessels (2x2000 litres) were installed to prevent the heat pumps frequent shunting down, and also for heat storage

- In this particular project, the power used to operate the VRF systems is produced by the renewable solar PV panels installed on the roof of this building. This makes the new heating system completely carbon neutral.

Details of the VRF systems are summarised in the following table:

|

System

|

VRF Outdoor Unit

|

VRF Indoor Unit – Floor Standing Hydro Kit

|

|

System 1

|

Product: Multi V 5

Model: ARUM320LTE5

Capacity: 89.6 kW

Power: 3 Phase, 50 Hz, 400 V

Refrigerant: R410A

|

Product: High temperature Hydro kit

Model: 4XARNH08GK3A4

Capacity: 25.2 kW

Power: 1 Phase, 50 Hz, 230 V

|

|

System 2

|

|

System 3

|

Product: Multi V 5

Model: ARUM400LTE5

Capacity: 112 kW

Power: 3 Phase, 50 Hz, 400 V

Refrigerant: R410A

|

Product: Low temperature Hydro kit

Model: 4XARNH10GK2A4

Capacity: 31.5 kW

Power: 1 Phase, 50 Hz, 230 V

|

|

System 4

|

All refrigerant pipework and accessories in the VRF systems were thermally insulated appropriately according to project design specifications. The controls of the VRF systems were connected to the existing BMS of the building.

A typical schematic diagram of the VRF system is shown in the following figure:

Conclusion

This case has demonstrated that by combining with other renewable technologies, it is possible to use VRF system to provide carbon neutral solutions for refurbishing existing buildings.

Heat pump technology, as one of the very best low carbon options currently available in the market, can also be used for other solutions.

- In conjunction with a hydro kit, it can produce Domestic Hot Water (DHW) for building occupants, or hot water used in underfloor heating systems.

- In combination with refrigerant based regular air conditioning indoor unit, VRF can be used for space heating and/or cooling. When configured as a heat recovery system, the indoor units can be heating in certain areas whilst cooling in others simultaneously. The energy recovered from the indoor units operating in cooling mode, can be transferred to other units operating in heating mode, and vice versa. It offers great design flexibility and has huge potential to grow.

To help to decarbonise the existing building’s stock, there is no doubt that heat pump technology will play an important role to replace conventional fossil fuel heating systems in these buildings. This is a typical example of using heat pump to reduce carbon emission in retrofitting an existing building.

It is hoped that this project can serve as an exemplary case to inspire other renovation projects in retrofitting existing buildings to help to reduce carbon emission and achieve the long term goal of net zero target.