The reasons for global warming are still scientifically undefined but the general trend favours industrial pollution as the main cause. The debate is gathering pace as more countries experience freak weather conditions, one being instances of severe flooding.

Apart from the obvious direct effects of the flooding and those unfortunately affected by them, there are further hidden perils lurking in the huge volumes of water being released into the atmosphere as the moisture evaporates from the saturated land.

The result is manifested in high humidities, which can be severe in some industries. It is fair to say that most products are unaffected by ambient temperature but most products are affected by moisture.

Meteorological trends

Air conditioning is generally misunderstood as simply a means of temperature control. In today's changing environment however, this is no longer enough. Most existing air conditioning systems have experienced a shortfall in capacity during recent times because of the significant increases in dry and wet bulb temperatures.

The trends for the last 20 years in the UK have been startling. In 1990 the summer design maximum for wet and dry bulb was 26.5ºC db and 19.25ºC wb (equivalent to 11g/kg absolute moisture content). This figure was commonly used by consultancies and industry alike.

By 1995 this had increased to 28ºC db and 21.25ºC wb (13g/kg). 1998 saw a further increase in dry bulb design temperature after the UK experienced summer high peak temperatures in excess of 30ºC the previous summer. This resulted in design values of 30ºC db and 21.25ºC wb (13g/kg) being commonly used. Nowadays it is quite often the case that a figure of 35ºC db and 24ºC wb (14.1g/kg) are realistic design conditions.

Admittedly not everyone is using such design criteria, therefore the overall trend is the important point.

Potential problems

Excessive dry bulb temperature mainly affects staff comfort when capacities of cooling equipment are exceeded. The mechanical integrity of plant also gives concern if ambient dry bulb temperatures pass beyond maximum condenser design.

This latter point can be simply resolved with the introduction of adiabatic cooling pads fitted in front of the condensers removing the excessive sensible heat. However generally speaking, providing the cooling equipment is in good order the problems of excessive dry bulb temperature is tolerated without too much disruption to production.

This is not the case with excessive ambient moisture levels. High absolute moisture levels can create problems in all sorts of different ways at any stage during the life of a typical industrial process or product. The difficulty is identifying moisture as the root cause.

Some typical problems caused by high humidity are:

· Cooling plants overloaded due to high latent load

· High moisture levels in packaging areas creating equipment difficulties

· Raw materials spoiling in unprotected warehouses

· Finished goods packaging softening as it absorbs moisture

· White goods rusting in unprotected warehouses

· Blast freezers icing up rapidly giving product core temperature drift

· Cold store temperature drift with excessive ice build up on evaporators

· Condensation in food preparation areas giving health and safety risks

· Cooling tunnels suffering from condensation spoiling unwrapped product

Potential solutions

Everyone has heard of dehumidification but very few understand the intricate design details required to size plant accurately. However, the basic fundamentals of dehumidification are quite simple and easily explained. Once understood, they should be considered carefully to ensure the correct type of dehumidification is chosen to suit each particular application.

There are three ways to remove moisture form air:

· Cooling it to condense the water vapour

· By increasing its total pressure which also causes condensation

· By presenting a desiccant to the air which pulls moisture from the air through vapour pressure differential.

Information concerning pressure-based dehumidification can be found in references addressing compressed air.

The types of dehumidification commonly used in industry are:

· Cooling based dehumidification, including direct expansion systems, chilled water systems

· Chemical dehumidification (desiccant), including liquid spray towers, solid packed towers, multiple bed, rotating honeycomb

Generally speaking, the principle desiccant system commonly used is the rotating honeycomb (desiccant rotor type)

Cooling-based dehumidification

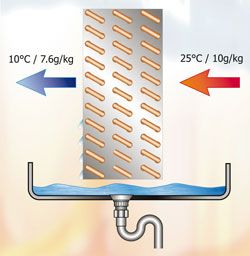

Most people are familiar with the principle of condensation. When air is chilled below its dewpoint temperature, moisture condenses on the nearest surface. The air has been dehumidified by the process of cooling and condensation. The amount of moisture removed depends on how cold the air can be chilled - the lower the temperature, the drier the air.

This is the principle behind most commercial and residential air conditioning systems. A refrigerant system cools air, drains away some of its moisture as condensate and sends the cooler drier air back to the space.

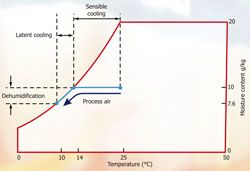

Fig 1: Cooling-based dehumidification: by chilling air below dewpoint, moisture condenses and the air is dehumidified

Cooling based dehumidification: by chilling the air below its dewpoint, moisture condenses and the air is dehumidified.

Dehumidification through air cooling can be illustrated on a psychrometric chart. Air is cooled from 25ºC to 14ºC, no moisture is removed. But when the air is at 14ºC, it is saturated - 100% relative humidity - and if we cool the air further moisture will have to condense out of the air. If we cool the air from 14ºC to 10ºC we will remove 2.4g of moisture through condensation - the air has been dehumidified (see fig 3).

The actual hardware that accomplishes cooling dehumidification is exceptionally diverse and thousands of different combinations of compressors, evaporators and condensers are in use throughout the world.

There are three basic equipment configurations of interest to designers of humidity control systems:

· Direct expansion cooling

· Chilled liquid cooling

· Dehumidification re-heat systems

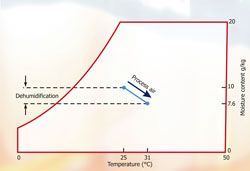

Fig 2: Dehumidification reheat: The dehumidified air is reheated before returning to the space

Direct expansion cooling

Direct expansion systems allow the refrigerant gas to expand directly into the air-cooling coil removing the heat from the airstream. Residential air conditioners and commercial rooftop cooling packages are generally direct expansion systems. They are often called DX units

Chilled liquid cooling

Chilled liquid systems use the refrigerant gas to cool a liquid which is then circulated through a cooling coil to cool the air being dehumidified. These usually use chilled water, glycol or brine.

In air conditioning applications these tend to be more complex and expensive than alternatives. As a result chilled liquid systems are more often used in large installations where they have many advantages of installed cost and operating efficiency over DX systems.

Dehumidification reheat system

Dehumidification reheat systems can use either direct expansion or chilled liquid for cooling the air but, following cooling, the air is reheated before it is returned to the space. Most common residential dehumidifiers use this configuration. Commercial and industrial versions are generally used in high temperature and high humidity environments such as swimming pools, timber drying kilns and heat pump chambers for confectionery drying.

Limitations may become apparent when using cooling for dehumidification when the cooling process freezes the moisture in the air rather than simply condensing it to a liquid.

Fig 3

Frozen condensate causes two problems for a cooling system. Firstly, the frost insulates the refrigerant from the air passing through the coil and this reduces the heat transfer capabilities of the equipment. Secondly, the frost physically clogs the coil reducing the airflow. Eventually the frost blocks the airflow all together and dehumidification ceases. Systems that cool the air to around 0ºC require sophisticated defrost systems to melt the frozen condensate from the coil. Dehumidification and cooling stops while the coil defrosts.

The specific dehumidification capacities of cooling systems are highly dependent on hardware and generally can be misleading. It is enough for an engineer to realise that while cooling systems dehumidify at high temperatures, special precautions are necessary when using cooling systems to dry air below a 5ºC dewpoint. (5.4g/kg)

With thanks to Mike Creamer of Business Edge who revisits his Masterclass series of articles, updating and adding to the information which proved so useful to readers when the series was first published over ten years ago. In this reincarnation, the series will cover both air conditioning and refrigeration and serve as an on-going source of technical reference for experienced personnel as well as providing a solid educational grounding for newcomers to our industry.