Geoff Lockwood, technical director of Ebm-Papst UK, looks at the huge carbon savings being made by BT after adopting new air conditioning equipment using EC fan technology

As the largest exchange provider in the UK, with 6,500 sites, BT is responding to the increasing broadband demand with a new IP-based communication system, 21 Century Network. The main drivers behind BT’s multi- billion pound investment are cost, reliability and, in particular, life cycle costs. The UK air conditioning industry has responded to this demand with new air conditioning technology encompassing Ebm-Papst’s EC fan technology.

The air conditioning in the BT installations is manufactured and installed by two main air-conditioning equipment manufacturers, the Eaton-Williams Group and the Weatherite Group, both of whom utilise these new EC fans. The installations are both new build and retrofit.

New build

For new build installations a range of DX, 8kW to 45kW, and fresh air cooling units, 0.5 m3/sec to 6m3/sec, are used by BT.

These new developments have included the replacement of forward-curved fans driven by three-phase motors which have a fixed speed and are adjusted from transformers. These have been replaced with new EC technology using a backward-curved impeller on a DC motor, speed- controlled with electronic commutation via a

0-10V control line. This allows the fan to provide the most efficient air movement solution combined with 100% speed control at peak efficiency.

The simple 0-10V control line and RS485 links have allowed a new full web-enabled control system to be developed. This has allowed the unit to run with maximum free cooling as the fans’ speeds can be smoothly operated between 20% and 100% of nominal speed. The maximum use of free cooling is a proven method of minimising compressor run time. Using this, in combination with the fan control, the supply air volume is easily adjusted to suit low-load conditions where large power savings can be made. System layouts have also been redesigned such that the use of full fresh air cooling can be exploited with minimum pressure drops thus reducing the motor power requirement for the air supply.

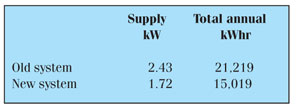

Table showing power figures for typical 22kW close control air conditioning unit used in BT installations

Retrofitting

Retrofit with EC fans in existing air conditioning units is also being carried out. This is an extensive programme and includes the replacement of up to 25,300 fans.

A range of scrolled and unscrolled centrifugal fans with backward curved impellers are being used due to space constraints. Up to 50% power savings are being realised in all cases.

Power savings for new build

Based on a typical 22kW cooling unit, an example of the power absorbed in ‘new system’ and ‘old system’ is shown below:

These figures show that by the use of EC fans and new control methods, the average absorbed power of the whole air conditioning unit is reduced by 42% or 3kW. This results in an annual saving of 25,987kWhr and is equivalent to 11.2 tonnes of CO2 per annum per unit or 2.9 tonnes of carbon per annum per unit.

Typically, 1,000 units are fitted new every year. This represents a ‘new build’ carbon saving of 2.9 ktonne of carbon per annum.

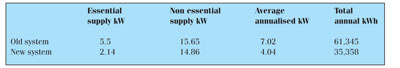

Table showing power figures for typical 30kW close control air conditioning unit used in BT installations

Power savings for retrofit units

A range of retrofits can also be considered due to the range of DX and fresh air units used. Typically a 30kW cooling unit example is shown below:

These figures show that by using EC fans, the power of the unit is reduced by 0.71kW. As previously, this results in an annual saving of 6,200kWhr. This is equivalent to 2.6 tonnes of CO2 per annum per unit or 0.7 tonne of carbon per annum per unit.

BT’s existing estate represents 23,769 fans, so this represents a carbon saving potential of approximately 13.6ktonne of carbon.

Reduced fan speed during recirculation

During low-load conditions, when the unit is in recirculation with minimum fresh air and no DX, the fan can be slowed (typically to 80% of the nominal unit volume). This halves the nominal current for, typically 10% of the fan run time.

More fresh air

The fully-enabled controller allows the fan speed to work in tandem with variations in the outside air and full fresh air damper. This enables the system to utilise full fresh air when the thermal dynamics are advantageous and to allow a reduced usage of DX systems. This in turn improves the lifetime of the DX systems and reduces the potential for leakage.

Refrigerant

All the DX systems utilise R407C and in the near future where DX is required, 410A systems will be developed. It is the aim of BT that the majority of future developments will remove refrigerant completely therefore realising further energy and environmental savings. This is currently under development for implementation this year.

Measurement and verification

The performance of the air conditioning units has been measured by the manufacturers to the relevant standards using calibrated equipment and all systems have been validated by BT engineers. This was done using a five-year field trial to ensure reliability and by witness testing with the manufacturers.

Verification of the data has been carried out by the contractors and witnessed and adjudicated by BT such that planned current loads meet actual values. The market involves competitive stances from a range of manufacturers although only two are highlighted here. In this instance the verification of performance by BT is part of the tendering process.

Costs

As you would expect the capital cost of the air-conditioning product is commercially confidential. However, power and reliability calculations show that the product pays back within the commercial target of less than 24 months.

Other installations and applications

The methodology used in this case study is a simple development of standard close control air conditioning technology and can be further exploited in both packaged and remote evaporator and condenser systems as EC technology is available in formats applicable for both.

Recent market research of the UK close control market suggest that approximately 150,000 new close control units are installed in the UK each year. These are used where environmental protection is paramount, such as in computer rooms and communication suites for a range of end-users from financial institutions to football clubs.

If it is assumed that for an ‘average’ unit around 2kW of running power can be saved per unit, then this would represent 2.6GWhr per annum of savings. This represents 1127ktonne of CO2 or 296ktonne of carbon. This represents 1.5% of the UK Kyoto targets.

The retrofit market has not been fully surveyed, but if we assume that each unit has a replacement lifetime of ten years then an estate of 1.5 million close control units in the UK would be reasonable. If by changing fan and control technologies approximately 0.7kW could be saved on each unit, this would represent a carbon saving of 1,036Mtonne. This represents a major contribution to the EU Kyoto targets1.

Close control air conditioning is paramount for the safe-running of communication systems. With the development of communication systems into the 21st century British Telecom has taken the decision to support UK plc with systems and employment for many years hence.

1. In all calculations of carbon saving, a ratio of 1kWhr to 0.43kg of CO2 or 1kWhr to 0.113kg of carbon was used.

Ebm-Papst UK

01245 468555