BALTIMORE Aircoil has launched a new closed circuit cooling tower, the HFL range, which can operate in three modes: combined dry/wet, adiabatic and fully dry.

An intelligent controls package switches between modes to match the cooling capacity to the load whilst achieving optimised water savings by operating in adiabatic or dry mode for as many hours as possible.

The HFL dry/wet cooling tower retains the benefits of closed circuit cooling where the water to be cooled is in a sealed circuit thus preventing contamination of the cooling water.

The HFL has a conventional hot-dip-galvanised steel heat exchange coil and a secondary water re-circulating system which are used during dry/wet and adiabatic operation.

The dry component of the cooling is achieved by a finned coil mounted above the drift eliminators of the wet section.

Principle of operation

In all modes the fluid to be cooled is fed to the finned coil where as much cooling as is economically possible is achieved. In dry/wet mode when maximum capacity is needed the fluid then passes through the wet exchange coil where evaporative cooling takes place to give low cold water temperatures comparable to a conventional cooling tower.

In this mode the secondary water spray pump is on and the water usage is the evaporation of a small portion of the secondary water together with some bleed-off to limit the levels of dissolved solids in the water.

In adiabatic mode, the spray pump remains on thus efficiently pre-cooling the air as it passes up through the tower. However, in this mode, the fluid to be cooled completely bypasses the heat exchange coil by means of a three-way valve arrangement. In this way no water is evaporated in cooling the fluid and the only water usage is the small amount of water evaporated to achieve the adiabatic pre-cooling of the air. The heat rejection from the fluid is achieved solely in the finned coil which is now more efficient due to the pre-cooling of the airstream.

In dry mode the fluid to be cooled passes through both the finned coil and the heat exchange coil. However, the spray pump is switched off so the coil is not wetted and the tower operates completely dry.

An intelligent controls package, temperature sensor and thermostat coupled with a three-way valve arrangement switches the operation between modes and also modulates the flow through the wetted heat exchange coil during dry/wet operation. By optimal use of the controls package 40% of the water usage in a conventional cooling tower can be saved.

Further capacity control can be achieved with two-speed fan motors.

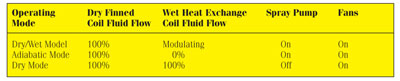

Table 1 shows the status of each element of the HFL

Construction benefits

The HFL dry/wet cooling tower has several unique construction features. When the spray pump is on the water falls into the sump which has a sloping bottom. This water drains directly into the wet sump where it is pumped back over the heat exchange coil. The wet sump is shielded from the airstream by a separation panel and an ingenious water lock. In this way the pressure difference between the inside of the tower, which is pressurised, and the wet sump, which is at atmospheric pressure, is maintained. This allows the wet sump to be accessed for inspection or maintenance whilst the unit is running. It also means that, when the spray pump is switched off, all the water drains into the wet sump and the remainder of the unit is totally dry.

Water treatment is required when there is water in the wet sump but the volume of water to be treated is far less than conventional towers thus saving chemicals and water treatment costs. In winter when the unit can run in dry mode for a prolonged period it is recommended the wet sump be drained during which time no water treatment is required.

When operating in dry/wet or adiabatic mode the construction of the HFL cooling tower complies fully with HSE Guidance L8 for the control of legionella. The unit has high efficiency drift eliminators, a sloping sump, construction materials which do not support microbial growth and ease of access for maintenance and cleaning.

A choice of corrosion resistant construction materials, including stainless steel, and a wide range of accessories and sound reduction packages make the HFL closed circuit cooling tower one of the most versatile on the market and equally suitable for air conditioning and process cooling applications. Capacities up to 2MW are available from the single unit.

Baltimore Aircoil

01895 814777