As building and construction is responsible for 39% of all carbon emission in the world as referenced in the World Green Building council embodied carbon report, with operational emissions (i.e., energy used to heat and cool and lighting the building) accounting for 28%.

The remaining 11% comes from embodied carbon emissions, or ‘upfront’ carbon that is associated with the materials and construction process throughout the building whole life cycle.

As 80% of exiting building will still be in use in 2050 when the Net Zero targets come into effect, it is crucial that building designs look to use lower embodied carbon products and more energy efficient HVAC systems.

Embodied carbon is understood as the greenhouse gas emissions associated with the manufacture of a product, its installation, maintenance, repair, replacement, and end of life. It covers the whole life cycle, excluding operational aspects and the potential recovery, reuse, or recycling of materials. The embodied carbon referred too is the equivalent global warming carbon dioxide measured in kg CO2 or Global Warming Potential (GWP). The embodied carbon associated with building services design can be significant over a building's lifetime, due to the materials used and replacement rates.

However, during the design stage the main previous focus tended to be more on minimising operational carbon emissions (i.e., amount of carbon emitted during the use of a building) however, the emissions relating to the rest of a building’s lifecycle were largely not taken into account.

With improvements in energy efficiency and tightening UK regulations (such as new Part L Building Regulations), the amount of energy used in the operation of buildings has started to decline. This has increased the importance of the energy used to build them in the first place, particularly if we are to meet the targets of delivering zero-carbon buildings.

A building’s whole life carbon emissions refers to both its operational and embodied carbon emissions, including as previously mentioned above, it’s materials, transportation of materials, the construction, repair, maintenance and even the deconstruction of a building.

Unlike operational energy, embodied energy savings have an immediate impact on a building’s whole-life carbon, and they are independent of the occupant’s behaviour. The choice of materials and construction methods can significantly impact the amount of energy embodied in a building. However, just as important as the energy embodied in a building’s fabric is the energy embodied in MEP equipment used to heat, cool, ventilate and light a space.

Therefore, the introduction of CIBSE’s new TM65 calculation methodology is a step in the right direction as this helps provide an opportunity for the industry to assess and evaluate the embodied carbon of MEP products by considering a number of factors:

- Product Life, Product Weight

- Product Materials

- Any Refrigerant Usage

- Product Maintenance / Warranty

- Operational Efficiency

- Factory Waste and Energy Consumption (inc. Does product manufacturer produce renewable energy)

- Percentage of Reuse or Recycling of Materials.

CIBSE’s new TM65 calculation methodology is a welcome starting point in the effort to increase visibility and transparency on life cycle impacts of MEP products.

Although it is widely recognised that Chilled Beams provide energy savings of typically 22 to 40% (see EDSL TAS Energy Study), there use can also reduce the buildings embodied carbon when compared to other HVAC systems. As Chilled Beam Technology operates using clean potable water as the cooling medium that is distributed through the building, it ensures the buildings HVAC system uses the minimum volume of refrigerants, which therefore also minimises the volume of any refrigerant leakage, which considerably lowers the buildings GWP (global warming potential) and so lowers embodied carbon.

Also, as chilled beam technology have no filters that would require regular replacement and have no moving parts such as fans and motors, they require very little maintenance, and so have minimal green house gas emissions associated with their low maintenance and low repair.

As chilled beams are manufactured from copper and aluminium (i.e., heat exchange coils) and Zintec steel (i.e., casing & support structure) the products can be fully recycled at the end of the products life which reduces the embodied carbon associated with ‘disposal’.

It is also important to highlight that the materials that are used in Frenger Systems chilled beam product construction already contain a recycled content to help reduce the amount of virgin material being used and are fully recyclable at end of product life to help minimise material waste.

Both Franger’s Active and Radiant Passive chilled beam products also allow the opportunity for exposed installations which can further help to remove the need for a suspended ceiling system offering dematerialisation of the interior components to lower the embodied carbon.

In a recent UK Green Building Council study looking at Net Zero office design a 14% saving in embodied carbon was achieved by simply removing the suspended ceilings materials and removing the regular need to replace ceiling components/materials during life of office building. This option is achievable with chilled beams given they provide low noise operation and good thermal comfort levels.

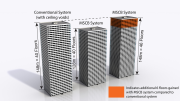

Chilled beams offer the additional benefit of reducing the overall floor construction height which can help lower the embodied carbon of the building due to reducing the building construction materials.

Frenger has also successfully supplied both their Active and ‘Radiant Passive’ Chilled Beam product solutions to old heritage buildings to enable the building fabric to be re-used which is valuable not only for preserving heritage but contributes to a significant reduction in the carbon footprint of the redevelopment.

From a life-cycle assessment study undertaken by one our Franger’s clients for a project that they supplied in Sydney, Australia, they calculated that the value of retaining the heritage façade, floors and column structure to be a 24% reduction in embodied carbon compared to conventional construction. Such to the success of the project the developer even relocated their headquarters to the building to showcase their capabilities as an innovative builder.

Frenger has invested in research and development test laboratories (3 x Climatic, 2 x Photometric Lighting and 1x Acoustic test laboratories ) at its facility on Pride Park Derby. It has also heavily invested in installing photovoltaic panels onto its UK production facility to enable on-site renewable energy to help reduce their overall embodied carbon as a first tier manufacturer.

By manufacturing locally in the UK this also reduces emissions associated with the delivery of finished manufactured products to the project site(s).

The above translates to Chilled Beam Technology being an ideal solution to help reduce carbon emissions for many project applications such as Educational Facilities, Healthcare & Hospital applications, Commercial Office Space and Hotels and leisure facilities. Frenger offers chilled beam solutions for both new building construction and retrofit projects.