THE use of CO2 in a leading Swiss supermarket is said to have shown significantly better performance than systems using R404A

FOUNDED by Pierre Demaurex in the 1960s in Geneva, Aligro has been the undisputed number one among the bulk supermarkets in French-speaking Switzerland for the last 30 years.

Last fall, Dominique and Etienne Demaurex, sons and successors of Pierre Demaurex opened the third Aligro market in Sion. This store boasts a total floor space of 12,500m2 of which 5,000m2 is sales floor.

LKS KälteSchweiz AG/LKS FroidSuisse SA, a subsidiary of Carrier/Linde Refrigeration, was responsible for the overall refrigeration and control technology in the normal area and deep freeze area of the supermarket. Three compressor units were supplied, as well as display cases with a total sales length of 180m and equipped the nine walk-in cold rooms with floor space of approximately 200m2. In addition, Carrier/Linde Refrigeration equipped the five deep freeze cells with floor space of approximately 90m2.

For normal cooling, the new CO2 composite cooling system CO2OLtec by Linde Kältetechnik was used. Control and monitoring of the NC compressor units, which also work in the transcritical area, is handled by the newly-developed Eckelmann VS3000C. All sales display case evaporators and cooling room evaporators are equipped with electronic expansion valves.

The required overall cooling capacity for the normal cooling area is 322 kW. It is divided into two separate integrated refrigeration units each with identical cooling capacities. The deep-freeze area has a cooling capacity of 67kW. Its heat is dissipated in cascade operation by CO2 evaporating directly from the normal cooling systems. In the sales areas as well, the direct expanding carbon dioxide ensures heat dissipation in the normal as well as in the deep-freeze area.

A CO2 gas cooler in V-block design is used for transferring the heat (2 x 236kW) that needs to be dissipated to the ambient air.

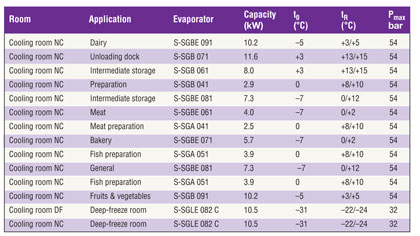

Cooling rooms with CO2 supercritical and deep-freeze rooms with CO2 subcritical. Equipped with Kuba CO2 evaporators

In the sales areas, customers can find fresh and frozen goods in a variety of different cooled shelving, chill counters, islands and deepfreeze combinations from the Linde Evolution 5 series, as well as in a larger number of walk-in cold rooms and deep freeze rooms. In these areas CO2 air coolers from Kuba are used exclusively.

Heat recovery is utilised throughout. Thus, hot water for heating at 2 x150 kW is available during the heating season and hot service water at 90kW is available year round.

In the normal cooling system, the compressor unit system was divided into two pressure areas for the dimensioning of components. The high-pressure area was configured at a maximum operating pressure of 115bar. This area includes the high pressure side of the compressors, the heat recovery system, the hot gas and liquid line to the gas cooler, all refrigeration components on the high-pressure stage, as well as a special high-pressure valve.

The maximum operating pressure for the other system components, for example the collector or the liquid and suction line, is only 40bar. The evaporators in the normal cooling system are optimised on the refrigerant side for CO2 for technical flow reasons and configured for the higher pressure loads. Thus, for the greater part of the systems, standardised commercial refrigeration components could be used that among other things can also be used in CO2 deep freezing.

Running costs are important when operating a refrigeration system and the refrigerant used is of crucial importance in this regard. If high outside temperatures are assumed, then R404A is said to show clear performance advantages over CO2.

“However, if the favourable thermodynamic and technical thermal characteristics of CO2 are taken into consideration, there is a different picture,” emphasises Marcus Höpfl, manager of the Buchser subsidiary and member of the management team of LKS KälteSchweiz AG.

He cites the following reasons:

• Due to better heat transfer ensured by CO2, it is possible to operate equipment at an evaporation temperature that is 2K higher compared than R404A.

• With CO2 being a high pressure refrigerant, there is a saturation temperature loss in the suction line that is reduced by 1K compared to R404A, assisting oil return to the condensers. The CO2 condensers in the normal cooling system can be operated with vacuum pressure, corresponding in total relative to R404A to a saturation temperature that is 3K higher.

• The special characteristics of the transcritical process control and the good heat transfer characteristics of CO2 in the gas cooler enable cooling of the pressure gas close to ambient.

• At lower air temperatures a reduction of the condensing temperature to approximately +10°C is possible when using CO2. The reason is that a sufficiently high differential pressure exists relative to the evaporation pressure due to the higher pressure level of CO2 even at these low temperatures.

• The current energy consumption of NC/DF DX CO2 systems is approximately 15 to 20% lower than comparable NC R404A systems with refrigerant/re-cooling system and DF DX. The energy data are based on measurements performed over a period of 12-18 months.

• Current investment costs of NC/DF DX CO2 systems are equivalent to R404A, providing the NC system is more than 220kW or the surface area of the supermarket exceeds 2,500m2.

For Marcus Höpfl, the results are clear: “CO2 should be looking at an exciting future as refrigerant. Currently its implementation in refrigeration applications is somewhat more expensive because the necessary components are not yet being produced in the same quantities as are produced for systems that work with fluorinated refrigerants. Currently this acts as somewhat of a brake on demand. In the future, however, there will not be a price difference even at lower system capacities.”

Grasso Products

01600 891010