Variable speed control

By varying the speed of a compressor you vary its capacity and power input. The extent to which capacity is varied is very much dependant on the design of the compressor and some machines simply do not offer any real advantage in this regard.

Before progressing further on this type of capacity control, it is important to remind ourselves of two key factors in relation to the variation in thermal load upon the conditioned space, these being true for comfort/close control air conditioning and refrigeration:

a) As the load increases within the conditioned space, the temperature will increase beyond the desired condition.

b) As the load increases within the conditioned space, the evaporating pressure will increase. So too will the evaporating temperature and suction pressure at the inlet to the compressor.

Whilst a) is obvious, b) is very important in terms of exercising control over the system, particularly where several evaporators are served by a common single or multiple compressor arrangement.

The load on nearly every system is infinitely variable, and in many cases falls to zero, particularly in the field of comfort air conditioning. The ideal system should therefore be able to follow and meet this fundamental requirement. The industry has however waited decades for this advance.

In order to match the system capacity exactly to the load, it is necessary to detect the deviation in space condition and the increase or decrease the compressor speed accordingly until the new load is perfectly matched by the new level of cooling capacity. This can be achieved with a temperature sensor located in the return air stream which is read by a micro-processor controller. The controller will compare the actual temperature with that of the setpoint temperature, and will output the necessary adjustments to a power inverter, which in turn controls the speed and capacity of the compressor.

Alternatively, a suction pressure transducer is positioned in the suction line and reads the instantaneous suction pressure. This is fed to a micro-processor controller which then compares this reading with a suction pressure setpoint value. Again, the controller will output the necessary adjustments to a power inverter, which in turn controls the speed and capacity of the compressor.

The suction pressure setpoint can be directly related to the evaporating temperature via the pressure-temperature relationship of the refrigerant being used in the system. This will then ensure that the correct apparatus dewpoint and equipment sensible heat ratio are obtained.

Power inverter

Power inverters are available in single and three-phase versions. In either case, the power inverter takes ac power and converts this to dc. The dc supply is then re-converted to ac. However, the inverter’s integral microprocessor then controls exactly the amplitude and frequency of the resulting ac output to the drive motor. Since it is frequency that governs the speed of the drive motor and compressor, it is frequency that is varied according to the refrigeration systems requirements in terms of either temperature or suction pressure adjustment. As the space temperature or suction pressure increases, so too does the frequency of the power supply to the drive motor/compressor thus increasing capacity until the desired setpoint is restored. The normal UK supply voltage frequency of 50Hz can be converted by a power inverter to as high as 460Hz thereby enabling compressor to be driven at incredibly high speeds. Some compressor designs are capable of being driven at several thousand rpm.

The load in the conditioned space normally varies due to changes in internal thermal gains and variations in ambient design temperature. These changes affect both the evaporating and condensing temperatures and subsequently the evaporating/suction and condensing pressures. This in turn causes major changes to the compression ratio and subsequent loading on the compressor and required torque at the drive motor shaft. It is therefore essential for the voltage applied to the motor to be continuously varied to match the load and maintain the correct electrical current levels at the motor.

Current sensing transducers continually monitor the current being drawn by the motor which is directly related to load and torque. The power inverter makes continual and very rapid adjustment to the voltage applied at the motor. This sophisticated level of control affords enormous protection to the drive motor and, when correctly set up, prevents the motor from ever experiencing a burn-out condition. Protection against phase failure, phase angle and ground fault are also included.

We now have an inverter connected to the compressor drive motor and the inverter is controlled by a microprocessor in accordance with a temperature sensor or pressure sensor reading. The power inverter can control the motor speed in virtually infinite steps through out its entire speed range.

The maximum speed of a compressor drive motor is normally the equivalent of the 60 cycle mains frequency. If a motor has a standard speed of 1450rpm (1500 synchronous) at 50 cycles it will operate at 1750rpm (1800 synchronous) on a 60 cycles mains supply. Most manufactures design their products for use at 60 cycle frequency as this the standard frequency in the USA.

In addition to reducing the speed an inverter is also capable of increasing motor speed above its standard rating. This allows the losses for slip to be compensated (1450 versus 1500rpm or 1750 versus 1800rpm).

The constraints on the minimum speed are dictated by the ability of the oil pump to maintain adequate oil pressure and oil supply to the vital parts of the compressor. On certain compressors, this is normally between 600 and 800rpm although some machines will run as low as 200rpm. The other limitation is of course the maximum speed which is governed by the design and configuration of the compressor. The writer has designed and installed variable speed refrigeration systems with compressors operating up to 3000rpm (100Hz). The energy efficiency of inverter controlled systems are far superior to cylinder unloading installations and many other types of capacity control. Where reciprocating compressors are concerned, the volumetric efficiency of the compressor can increase dramatically as the compressor speed is reduced and since many systems spend most of their lives at part load, this is a very important consideration where running costs, conservation of fossil fuels, global warming and pollution are concerned.

Multiple-compressor systems

Multi-compressor systems are mostly encountered on large installations which have a great number of evaporators which are individually controlled. With this type of system there is always a demand for cooling capacity but the fluctuations in load can be significant.

There are two basic types of multi-compressor system, the most common being a number of compressors, all of equal size and the less common type having a number of unequal size compressors.

Multi-compressor equal sized compressors

In this type of installation two or more compressors of equal size are connected in parallel to a common suction line and a common discharge pipe. Each compressor represents a percentage of the total load, therefore by switching a compressor on or off; the capacity of the entire system is affected. If the system comprises four compressors, each compressor represents 25% of the system’s capacity. The operation of the compressors is controlled by the suction pressure which may be sensed by a pressure transducer which activates a logic controller which in turn controls a multi-step switch (electronic or electro-mechanical).

The logic controller on this type of system has to perform a number of functions in addition to responding to the pressure transducer. The controller must store the number of starts per hour of each compressor and it must record how long a compressor has been off. The object of this information is to ensure equal run time for all the compressors on the system and it must minimise the number of starts on each machine.

For example, if a four compressor system is operating on a load of between 80% and 90% there is a high probability that unless precautions were taken, there would be excessive cycling of the fourth and last compressor in the chain. It may be possible for the logic controller to widen the control differential before switching off and switching on but if this is not possible, the controller would select different compressors to start and stop in order not to exceed the safe number of starts per hour of all the compressors.

The number of steps of capacity of a system using equal size compressors is equal to the number of compressors fitted to the system. A four compressor system would therefore have 100%, 75%, 50%, and 25% capacity steps. The disadvantage with this type of system is the large percentage each step of capacity represents and the consequent frequent cycling of compressors to match small variations in load. Indeed, this approach can only hope to match capacity to load exactly at four points, the remainder thereby causing cycling of the compressors.

The energy efficiency of this type of system is better than the a cylinder unloading approach since, by switching a compressor off when the load is reduced, no power is wasted by running a machine at part load. However, because each compressor is such a significant percentage of the installed capacity and minor fluctuations can result in frequent cycling of compressors, the overall efficiency is adversely affected by the high energy usage during the start up phase.

Multi-compressor unequal sized compressors

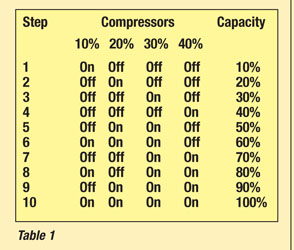

When unequal sized compressors are used a greater number of steps of capacity can be achieved. In the preceding example four compressors were used providing four steps of capacity each of 25%. If four unequal compressors are chosen, each having a capacity of say 40%, 30%, 20% and 10% then 10 steps of capacity becomes available as shown in Table 1. (Please note that other combinations would provide a number of intermediate steps of capacity.)

From Table 1 it can seen that unequal sizes of compressors can more closely match load variations and a suitably programmed logic controller can mix and match all the compressors to equalise running time between machines. The disadvantage with this type of system is that the largest compressor could fail. As this machine represents such a large percentage of the total capacity it is unlikely that the remaining compressors could provide adequate capacity during emergency or high load operation. Another consideration is that if the load on the system fluctuates significantly and rapidly, the starting and stopping of the various combinations of compressors could erode the energy savings which should normally be achieved by matching the load so closely.

In terms of energy efficiency this type of system, has the potential to be the most effective with the exception of infinitely variable speed systems. However, the characteristics of the load fluctuation will have significant influence on the operation of the compressors (see above)..

Mix and match

There is no reason why different types of unloading can not be combined to achieve the most effective capacity control system. For example, one of the disadvantages of the equal sized multi-compressor system described above was the fact that each compressor represented 25% of the installed capacity and therefore for minor load variations of say 10% to 15%, either the control band was widened or frequent cycling of the compressors had to be accepted. In order to avoid these compromises in system control, one of the system compressors can be fitted with either a cylinder unloading mechanism or with a power inverter for speed control. To take advantage of this configuration, the compressor fitted with capacity control would be the first to start and as the thermal load builds up on the system, the compressor would progressively load up its cylinders or increase in speed until it had reached its maximum capacity. At this point, one of the non-capacity controlled compressors would start and the unloading compressor would unload or reduce speed to a capacity to suit the total instantaneous load or its minimum capacity. This sequence of events would be repeated until the all compressor were running and system was is at its maximum design capacity.

When a reduction in load occurs, the machine fitted with capacity control would progressively unload or slow down until it reaches its minimum capacity condition at which point one of the compressors not capable of unloading would be switched off. The capacity controlled compressor may then have to load up or increase speed to match the load and again this sequence would be repeated until all non-capacity controlled compressors cease to operate and minimum load/ system capacity is attained.

The characteristic of inverter speed controlled compressors, being able to run in excess of 50 cycle speed was referred to earlier. This feature can be useful during the intermediate load phase of loading or unloading a system.

Let us assume that the load on a four compressor system had been reduced by 50% and two compressors are running to match this load. If there was then say a 16% increase in load, then instead of switching on a third compressor, the logic controller would allow the inverter controlled compressor to increase to 60 cycle speed to match the load. This would represent a significant energy saving. When one compressor on a multi-compressor system is fitted with capacity control then this compressor should always be the first to start and the last to stop.

Figure 1(not to scale)

While this situation would result in this compressor accumulating more running time than any other machine on the system and appearing to be the most likely to fail, this is not necessarily the case since the compressor run time will be offset by having least number of starts and it is generally accepted that it is during the starting phase most of the wear and tear takes place. One negative therefore one balances the other.

PSYCHROMETRICS - Part 1

The definition of psychrometrics can be said to be the study of dry air and water vapour mixtures. Having covered the mechanics of refrigeration we may now apply this knowledge to cool a given space.

The only source of cooling on any air conditioning system is the evaporator coil. Therefore, in order to remove heat from the space the heat must be transported in some way to the evaporator and the obvious medium used is the air contained by the room which is recirculated through the evaporator coil by the fan within the air handling unit.

In order to determine the quantity of air that has to pass through the evaporator we have to know the total amount of heat that has to be removed. This total quantity of heat energy comprises two forms, namely a given amount of sensible heat and the remaining amount of latent heat. It is essential to the efficiency of any air conditioning system for the heat gain calculations for the conditioned space to be as accurate as possible. The heat gain calculation will determine the absolute maximum amounts of sensible and latent heat gains to the space together with peak time of day and month of year. These two figures, sensible and latent heat, will determine both the characteristics of the evaporator and size of the air handler.

In order to design the “air side” of an air conditioning system we need to know the heat carrying capability of the air. There are a number of ways of establishing these characteristics including use of steam tables and psychrometric charts. We will concentrate on the psychrometric chart.

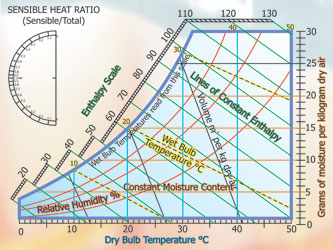

To start with we will briefly examine the structure of a psychrometric chart and see how the various processes are displayed on the chart. Fig 1 shows a skeleton chart that contains the outlines of the major functions. Note that there are several variations of psychrometric chart but that they all contain essentially the same characteristics:

Dry bulb (db) temperatures are read vertically from the X axis, until the db temperature lines intersect the saturation curve or wet bulb (wb) curve. For example, the 20°C db line intersects the wb curve at 20°C. However wb lines slope diagonally to the right and the 20°C wb line intersects all dry bulb temperatures greater than 20°C.

Horizontal lines intersecting the Y1 axis shows the moisture content of the air, in this example in grams of moisture per kilogram (g/kg) of dry air. This is also known as absolute humidity.

The specific enthalpy of the air is read from the enthalpy scale in kJ/kg. In Fig 1 above, the slope of these lines has been exaggerated in order to emphasis the difference from the wet bulb lines. When working with true psychrometric charts, care should be taken to avoid confusion between wb lines and specific enthalpy lines. Some charts use a separate set of scales external to the body of the chart and one uses a straight edge on these scales to determine the value within the area of the chart. Some American charts use the same lines for specific enthalpy and wet bulb.

Superimposed on the chart are lines of constant volume better termed specific volume. These lines show the specific volume of the air in m3/kg. Constant volume lines are usually shown widely spaced and readings have to be interpolated for a given condition.

Percentage saturation (more popularly known as relative humidity %RH) is shown as dashed lines in Fig 1 in order to differentiate between all the other lines shown on the chart and is termed %SAT.

Most charts enable the plotting of the sensible heat ratio (SHR) line. In Fig 1 this would be achieved by transposing the process curve from the main body of the chart to the protractor shown upper left.

Next month: We continue with the subject of psychrometrics

With thanks to Mike Creamer of Business Edge who revisits his Masterclass series of articles, updating and adding to the information which proved so useful to readers when the series was first published over ten years ago. In this reincarnation, the series will cover both air conditioning and refrigeration and serve as an on-going source of technical reference for experienced personnel as well as providing a solid educational grounding for newcomers to our industry.