Application and installation

Air handling units may be used in commercial, industrial, institutional, and government applications. Units can be arranged to operate in high and low velocity, constant and variable volume systems; as primary (fresh air) air plant for fan-coil, induction and room heat pump systems; as supply and extract air plant for single-duct, dual-duct and multi-zone systems; with special filtration for operating theatres, museums or clean rooms; with energy/heat recovery for industrial application, and for very quiet applications such as concert halls. Units may be accommodated in plant rooms or external to the building served, typically a roof location.

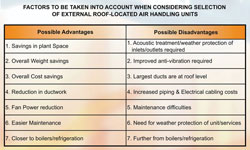

Before choosing to use external rooftop units possible advantages and disadvantages must be evaluated. Whatever the application or type of air conditioning or ventilation system, there are a number of important installation considerations:

· Space available and its location, for the unit and the connected piping, ducting and electrical services.

· Space/facilities for unloading and placing in position, installation (including assembly of sections, or where access is extremely restricted, for assembly of a 'flat-pack' unit in basic kit form), for commissioning, operation and maintenance and for component replacement.

· Foundations and supports (permissible structural loadings).

· Sound and vibration control requirements, relation of unit to critical areas.

· Location of fresh air intakes and exhausts (to avoid short-circuiting, contamination and noise problems).

· Routes/positions/sizes of supply and return air ductwork and piping, including mains water connections and drain positions.

Figure 1: Factors to be taken into account

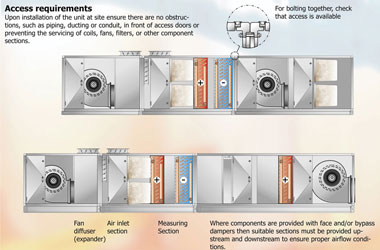

Figure 2: Air handling unit access requirements

· Building Regulations, fire and safety aspects, insurance company requirements, restrictions on unit or component construction, ratings or standards.

· Compliance with the construction (design and management) regulations including provision of access (platform/ladders) for maintenance purposes.

· Control and operational requirements, hours of operation, summer/winter changeover, day/night and weekend operation, frost protection.

With multiple units in a single plant room, some of these considerations need very careful study. A visual reminder (shown in figure 2) demonstrates the importance of ensuring proper and adequate access to unit components.

Figure 3: Commissioning/troubleshooting test readings

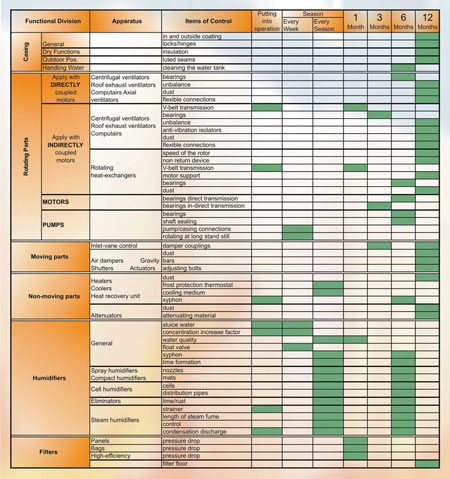

Figure 4: Systematic plan of maintenance

Ductwork connections

It is not always fully appreciated that poor design of the ductwork connected to the air handling unit, particularly at fan discharge, may have a seriously adverse effect on performance, leading to reduced airflow, increased motor power and unwanted noise problems (due to change in point of fan operation and air turbulence in discharge ducts). Discharge duct connections should be in accordance with good practice (See Fig.2).

Commissioning, operation and maintenance

Commissioning should follow the appropriate sections of the CIBSE series of Commissioning Codes (in particular, A: Air Distribution; C: Controls; R: Refrigerating Systems, and W: Water Distribution Systems). Particular attention should be paid to the Static Checks in Code A, to ensure that the air handling is in a satisfactory and safe condition prior to initial running.

Where the commissioning engineer requests the air handling unit manufacturer to assist in the evaluation of fan or coil performance then the necessary basic data should be collected and tabulated in a suitable form (as shown in Fig.3).

All air handling units require that a systematic plan of maintenance (such as that shown in Figure 4) should be rigorously implemented from the date of unit installation (just like a car, an air handling unit needs to be inspected and serviced during the warranty period).

All replacement items, particularly filters and drive belts, should be to original manufacturer's specification to ensure the unit performance is not impaired.

Next month: Part 34 Textile-based air distribution

With thanks to Mike Creamer of Business Edge who revisits his Masterclass series of articles, updating and adding to the information which proved so useful to readers when the series was first published over ten years ago. In this reincarnation, the series will cover both air conditioning and refrigeration and serve as an on-going source of technical reference for experienced personnel as well as providing a solid educational grounding for newcomers to our industry.