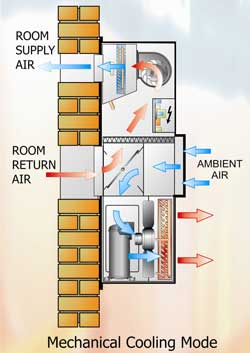

Fig 1: Close control mechanical cooling mode

Telecommunications high performance ac

The proliferation of telecommunications services, both public switched networks and cellular, has created an increasing demand for efficient and reliable precision air conditioning.

Both the sensitive electronic equipment and associated batteries should be kept at a constant temperature for optimal performance and maximum reliability. Even part of a network being offline can result in significant lost revenue for the service provider and may even encourage the user to change to the competition.

Introduction

Public switched telephone networks (PSTN) have traditionally been the major application for close control air conditioning equipment. Most switching centres and major exchanges have a medium to large heat load (30-300kW).

However the rapid growth of the cellular market has also led to a boom in smaller installations (heat load typically 1-15kW) to equip remote shelters or even containers used as cellular base stations.

The air conditioning requirements for telecommunications are not the same as those for computer rooms. We have defined precision air conditioning as 'the simultaneous control of temperature, humidity, air motion and cleanliness in a specified area, continuously and accurately'. Let us consider each aspect.

Temperature

Hitherto all engineers have agreed that it is necessary for maximum reliability to keep sensitive electronic equipment operating within a temperature range between 20-25°C. As semiconductor electronic components have become more efficient, it has been argued that higher temperatures may be permitted without loss of reliability.

The ETSI (European Telecommunications Standardization Institute) recommended environmental standard for equipment (agreed by the electronics manufacturers) permits temperatures up to as high as 40°C with a lower limit of 5°C.

However, the high heat loads generated by tightly packed electronic circuits can present a problem of localised hot spots in what otherwise may be an environment well within limits.

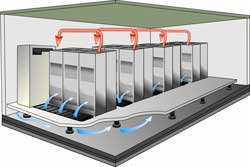

The elimination of such hot spots requires careful design of airflow distribution (See Fig 2) and can result in a theoretically very high air change rate or air recirculation rate.

Fig 2:Airflow distribution design

However, provided that the temperature in the hot spot does not exceed 40°C it may be more economic to accept a lower air recirculation rate provided that the general room temperature remains within an envelope of say 2-28°C.

One fact often neglected is the effect of heat on batteries. Even though the batteries used to provide 48V DC back up for the electronic switching equipment do not generate much heat, their reliability and lifespan are dramatically affected by fluctuations in temperature.

Sealed gas recombination cells commonly used in switching rooms are highly temperature sensitive. A variation of only 10°C above the normally quoted 20°C can shorten the quoted battery life by as much as 50%. The effect on a battery with a design life of ten years (at a temperature of 20°C) operating at 40°C would be to reduce its lifespan to three years or even less.

In practice with a temperature range between 22-28°C, the average temperature experienced by the battery bank is what counts. It would normally be impractical and uneconomic to control the temperature at the nominal 20°C, although on larger installations where there is a separate battery room, this is quite possible.

Relative humidity

In telecommunications rooms, the humidity range can be quite wide. The ETSI norm quotes a range between 10% and 85% RH, but great care must be taken with dry bulb temperature fluctuations! There is an unacceptable risk of condensation forming on sensitive components when the relative humidity is high and uncontrolled static discharges when the relative humidity is very low.

In practice it has been found in our climate that a humidity of between 30% and 70% at a dry bulb of 24°C can be achieved without special humidity control - ie, no humidifier. With their need for a dedicated water supply (simply not available at some remote sites) and their maintenance requirements, humidifiers are to be avoided if at all possible. Rapid changes in temperature and humidity are avoided by using appropriate control algorithms.

One pitfall is the freezing fog syndrome - potentially a serious problem if a unit is in fresh air free-cooling mode at low temperatures. A humidity sensor in the fresh air intake may cause the control to be overridden and the fresh air completely shut off so that the unit reverts to mechanical cooling.

Ventilation and air circulation

This is important - particularly for batteries. Even sealed gas recombination cells need moderate ventilation. Whilst rooms will be unoccupied for most of the time, it is important to provide ventilation for those occasions when service personnel need to access the equipment.

As already mentioned, adequate air recirculation minimises the effect of hot spots, and reduces the risk of rapid temperature and humidity changes.

Air filtration

Any build up of dirt on printed circuits and other electronic components can prove harmful.

Whilst conventional woven glass fibre G3 or G4 panel filters are suitable for the majority of applications, protection against gaseous air pollution in addition to particulate contamination may require activated carbon filters. Installations in marine environments also require special corrosion-resistant filters with stainless steel frames.

Year-round operation

Conventional comfort air conditioning systems are unsuitable for telecommunications applications, because they are not designed to operate throughout the year. They do not have energy saving features such as free cooling, or facilities for remote communication of alarm conditions.

Special purpose high performance air conditioning units are increasingly specified, with specially selected components for maximum reliability.

Larger systems are usually housed in secure buildings, and the air conditioning units actually situated within the switch room. Smaller cellular sites are by definition cramped for space, and the air conditioning system may be mounted on the outside wall or roof of the installation. Vandal- proof designs have to be considered, and the equipment has to be robust and proof against a wide variety of climatic conditions.

If for security reasons the air-cooling equipment has to be installed inside the base station, very small footprint units are demanded.

High performance air conditioning systems require electrical power for their operation, and the local mains power supply - especially in remote areas - may occasionally fail. An uninterruptible power supply (UPS) for the air conditioning at each site may be considered but there is a more economic solution available.

The communications equipment itself usually operates from a 48V DC supply with battery back-up. Versions of specialised air conditioning units are now available in which the DC is used to power the air circulation fans and controller. During a mains power supply failure, air continues to circulate through the space giving what may be a few vital minutes' operation whilst back-up action is taken.

Energy conservation

In any cooling system, the most energy-consuming items are the following:

· Air recirculation fan motor - continuous operation.

· Refrigeration compressor - intermittent operation dependent on cooling load.

· Condenser fan motor - intermittent operation dependent on cooling load.

The air recirculation fan selection is critical. It must provide sufficient airflow to meet the requirements of the site, and overcome the internal pressure drop within the air conditioning unit. This is made up of the pressure drop across the air inlet and outlet grilles, air filters, and cooling coil, and will be affected by the air velocity through the unit as well as the uniformity of air path. For this reason the face area of the cooling coil and air filters are maximised in the design.

Direct-driven, forward-curved centrifugal fans are used in many applications, although the increasing use of backward-curved 'plug' fans presents advantages in terms of space utilisation and energy efficiency.

The most energy efficient refrigeration compressors are semi-hermetic compressors, but these are only used on larger capacity systems (at least 20kW cooling capacity). Compliant scroll compressors have largely replaced hermetic reciprocating compressors - being up to 20% more energy efficient. Rotary compressors may be used on very small systems.

The condenser cooling fan is usually a large diameter axial fan running at the lowest speed consistent with the duty. The speed is automatically adjusted depending on the refrigerant head pressure, which is in turn dependent on the ambient temperature.

Units designed to be installed inside buildings may be fitted with plug fans - the additional external static capability available results in greater flexibility. The air supply to and from the condenser can be ducted from an outside location some distance away from the unit.

The design of the cooling coil is also important; a large surface area with a high sensible heat ratio more closely matches the characteristics of the heat load in the controlled space.

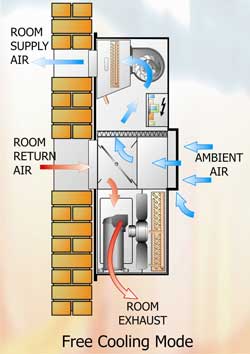

Fig 3: Close control free cooling mode

Free cooling

While mechanical cooling is essential in hot climates, for many countries the outdoor temperature is low enough to permit a more energy efficient method of cooling switchrooms called free cooling.

There are two main types of system - fresh air free cooling and glycol-free cooling. The former method is widely used for telecommunications; glycol-free cooling is only required when close humidity control is required, eg computer rooms associated with telecommunications networks.

With fresh air free cooling, air is drawn into the space at a temperature low enough to provide cooling by ventilation only. For example, if the temperature outside is 15°C, the temperature inside the switchroom can be maintained at 22°C without using refrigeration compressors.

The control system may be relatively simple. Above a pre-set ambient air temperature, say 15°C, the system changes over from fresh air free cooling to mechanical cooling. If the outside air temperature falls below 10°C, the unit reverts to recirculation mode with a small percentage of fresh air being introduced to pressurise the controlled space.

A more sophisticated control system is available which automatically adjusts the temperature at which fresh air free-cooling comes into operation in accordance with the heat load in the controlled space. It does this by comparing the return air and supply air temperatures - the larger the difference the greater the heat load.

Under low heat load conditions, the external ambient temperature at which free cooling becomes operational may be several degrees higher than for units fitted with the simple control.

The downside of many fresh air free cooling schemes tends to be high filtration costs for the contaminated ambient air that has to be cleaned.

There is also a trade-off between the large volumes of air which have to be handled in order to reduce the temperature difference between the outside ambient and the desired internal temperature, (thus maximising the fresh air free-cooling effect) and the fan motor power consumption.

It is also necessary to have access to an outside wall in order to bring in the fresh air.

In northern latitudes on the small number of days in the year when the temperature may exceed 30°C, the space temperature is still lower than 40°C. Many smaller installations in these regions therefore dispense with refrigeration compressors altogether.

Small cellular repeater stations are being installed in street furniture which relies on filtered fresh air cooling only - when the outside temperature is lower than 10°C the air may be partly recirculated to prevent the temperature inside the cabinet from falling too low.

The design of the filtration system for such equipment is very important; changing filters more than once a year is undesirable and the background contamination level in city centres may demand a high dust-holding capacity.

Such problems are overcome if outside air is not introduced directly into the cabinet but is passed over an air-to-air heat exchanger that is in contact with internally circulating air. Because of the intermediate heat exchange process, the upper operating temperature limit is about 7°C lower than with the direct ventilation approach.

Installation and maintenance

The special purpose air-cooled packaged units described present numerous advantages, as no specialised refrigeration installation is required. They can be fitted and connected up, and then switched on. It is usual for equipment redundancy to be allowed for so that one unit can be switched off for maintenance without disrupting the operation of the site. The controllers in each unit are usually linked to provide run and standby operation.

The filter units are disposable and many systems incorporate a means of monitoring the pressure drop across the filter. Once the initial pressure drop across the air filter has doubled, a signal from this air clog switch is fed into the alarm and monitoring system, alerting the service personnel to the need for changing the filters.

Controls and monitoring

Microprocessor controls also provide remote communications facilities that make it possible to provide local status and alarm information at the unit itself or remotely on a dedicated monitoring system. Facilities also exist for a service engineer to be sent a text massage on his mobile telephone giving brief details of any fault.

Next month: Close control air conditioning for industrial and medical applications

With thanks to Mike Creamer of Business Edge who revisits his Masterclass series of articles, updating and adding to the information which proved so useful to readers when the series was first published over ten years ago. In this reincarnation, the series will cover both air conditioning and refrigeration and serve as an on-going source of technical reference for experienced personnel as well as providing a solid educational grounding for newcomers to our industry.