Fridge companies collaborate to design the ultimate energy saving supermarket system

IN A unique collaboration, a group of UK companies and individuals with expertise in different areas of refrigeration have got together to look at how individual components within a supermarket refrigeration system react together to reduce energy consumption. There is an abundance of energy saving components available to the system designer but little is known as to how the addition of one component might have a detrimental effect on another, as far as its energy saving capabilities are concerned. Changes made in one area of a system may critically affect another. For instance, the use of night blinds may reduce the heat load within a display case but may cause short cycling and increased energy consumption at the compressors if the design has not allowed for this reduction in load.

The group, made up of experts from consultants Retail Engineering Support, pack manufacturers Robert C Scutt, controls manufacturer Tektronics, acoustics specialists Acoustical Control Engineers and display case manufacturers ISA, are looking at the theoretical application of thermodynamics, linked to compressor design, electronic speed control, electronic refrigerant flow control, electrical design, display case development, practical refrigeration plant design and acoustic and vibration technologies.

In order to fully understand and evaluate the system, the group has installed a convenience-store-sized supermarket refrigeration system in a facility near Cambridge and is able to operate and test the whole system for performance and energy efficiency.

The technologies

Four basic technologies are being used: electronic flow control; electronic variable speed electric motor drives; compressor design integrated with variable speed drives; air flow and acoustic/vibration control.

The idea is to combine all of these technologies into a cohesive system design which makes best use of all the integrated technologies for maximum possible savings.

Software to drive the electronic valves has been designed by Nottinghamshire-based Tektroniks, providing full modulation of the Danfoss AKV expansion valve. The smoothing out of the load fluctuations that this software allows has a significant effect on the energy consumption of the compressors.

Trials at a test site proved that on the multi-compressor system installed the savings were 13% over standard externally equalised thermostatic expansion valves.

Variable speed drives were used on the test system in order that the smoothed load produced by the electronic expansion valve could be consolidated and perhaps improved by compressor load matching.

A variable speed drive compressor was trialled at the test installation with impressive results and the group is currently in the process of improving the control function and integration of this technology.

The compressor capacity is modulated in line with the load variations, giving the advantages of reduced compressor cycling and steady-state operating conditions.

Air flow and acoustic/vibration design

In-town locations of convenience food stores are leading to increasing demands for low-noise equipment. The expertise within the group not only has the ability to carry out intensive analysis of an installation but also have the manufacturing resources to construct enclosures to meet the strict criteria being imposed by local authorities.

Low energy project test report

The test site, representing a small convenience store was completed last year and a trial carried out to determine if the energy efficiencies calculated by computer modelling could be verified in practice.

The system included three Bock HGX22P-190-4 HT compressors with a swept volume of 190m3; two Bock HAX34P-380-4 LT compressors with a swept volume of 380m3; and a Roller ALV-VL080-2N condenser fitted with two Ziehl Abegg fans.

The five compressors were mounted on a single base frame and configured in a dual temperature arrangement with separate HT and LT suction connections and a common discharge connection.

A discharge oil separator and reservoir was fitted with oil distribution to Optronics oil level control on each compressor.

The Tasselli display cases installed by ISA UK comprised four 1.88m dairy cases, a 2.5m meat case, 3.75m dairy case, a four-door, full glass door, frozen food case and a 2.5m half glass door over well, frozen food case.

Total HT load was 20kW at -8°C evaporating temperature and total LT load was 5kW at -36°C evaporating temperature.

Compressors were selected at the following conditions:

HT LT

Saturated suction temperature -10°C -38°C

Saturated condensing temperature +40°C +40°C

Design ambient temperature +32°C +32°C

Useful superheat +5°C +5°C

Non-useful superheat +15°C +28°C

Liquid sub-cooling +5K +5K

Refrigerant R404A R404A

Trial phases

Phase one trials have been carried out and the results are shown in the tables on this page.

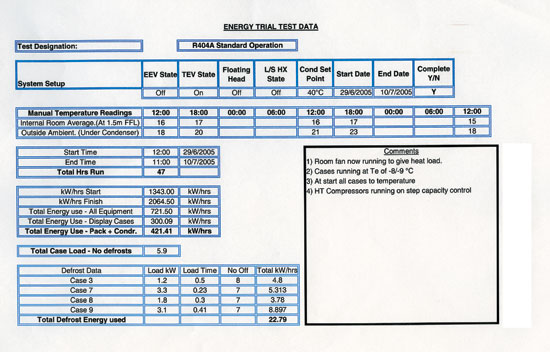

The first phase trial results: Standard operation

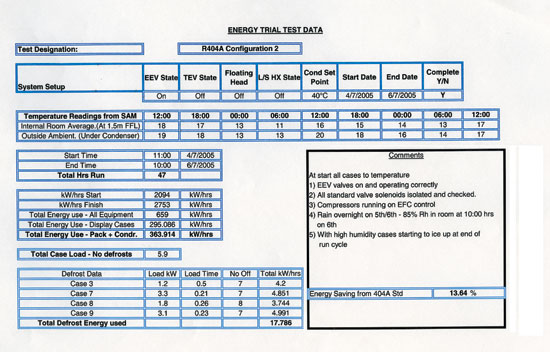

Configuration 2

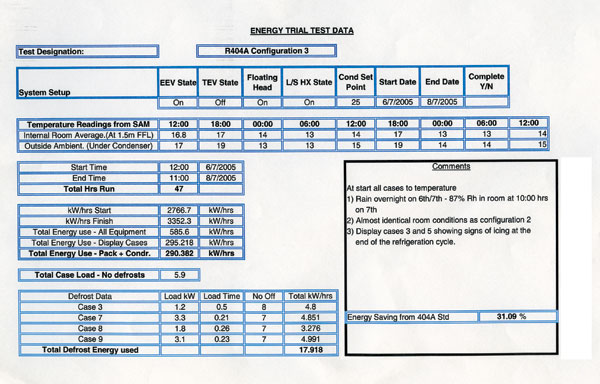

Configuration 3

The results have been set up to enable the display case constant load and defrost loads to be excluded if required. The reduction of energy indicated in the comment boxes are based on pack and condenser energy use. The group is currently investigating the results of refrigeration compressor arrangement, control and refrigerant flow control efficiencies.

It can be seen from the results that any variation in trial time and defrost cycles will be corrected with the spread sheet calculations.

The air temperatures were reasonably constant, however, room humidity was high during the configuration 2 and 3 trials. The humidity manually recorded in the room was as high as 87% during these tests. The humidity in the standard trial was recorded manually at 70%.

It can be concluded that the load on the refrigeration compressors was increased due to the humidity in configurations 2 and 3. However it was noticed that towards the end of these trials there was signs of two of the case coils beginning to ice up. This would have tended to reduce the load so it was assumed that these effects taken together would balance each other out.

Since the display cases are located in an area that is not held at fixed laboratory conditions, the group maintains that the overall results are more likely to indicate the reality of the savings within an operating supermarket.

The energy readings recorded are:

R404A standard trial 421.41 kW/hr

Configuration 2 363.914kW/hr

Reduction in energy: 13.6% from std

Configuration 3 290.382 kW/hr

Reduction in energy: 31.09% from std

For a full year of operation, the energy used would vary from the figures above. The group expects a lowering of energy use with ambient temperatures below 10°C and an increase with temperatures above 25 °C.

These tests are ongoing and the results are encouraging. In addition there are four units now running at various facilities: supermarkets, delis, food storage and food processing.

For further details contact Paul Scammell on 07974 986649