With energy costs spiralling out of control it is worth revisiting the Versatemp system says Clivet UK md Lance Joy

HEATING and cooling premises in order to provide a comfortable environment for occupants is often a challenge and one that can prove to be expensive. It is typical for most premises and building complexes to have variable climatic requirements, with certain areas requiring heating at the same time as others requiring cooling.

Achieving the right balance can be made more complicated because of the daily temperature changes created through the effects of sunlight and shade.

Although fan coil and VRF systems can provide a conventional solution, there is an economic alternative that can give the flexibility that many buildings require. The system employs reverse-cycle water source heat pump units connected to a water loop, and is more commonly referred to as a Versatemp system. Most significantly, this type of heating and cooling system can, with careful planning, make use of the energy that many industrial processes and buildings literally throw away everyday.

These types of premises and operations consume vast quantities of energy which is changed into heat and has to be extracted and disposed of. Typically this takes the form of hot air extraction or water circulation. Similarly, there are many processes that use large amounts of energy to produce ice and cold water, which is eventually run off to waste. Within the retail sector, the heat created by the refrigeration systems for cooler cabinets and freezers is almost always rejected by fans to atmosphere at the exterior of the premises.

However, before being rejected, this heat could be passed through a reclaim arrangement and used for water heating.

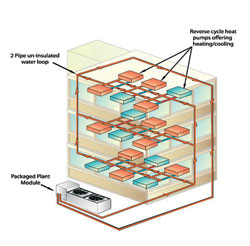

A typical Versatemp system layout

In manufacturing, many plants pay for energy used in extracting heat from a process and then pay once more for disposing of this heat. This generates very high energy costs, which could easily be recouped by reclaiming the heat and using it within a heating and cooling system.

With many conventional air conditioning systems, the heat within a given space is rejected to the atmosphere via a refrigerant based air-cooled condenser without there being any reclaimable energy benefits. Not so with the reverse-cycle water source heat pump system which employs water as the transfer medium, maintained within a predetermined operating band. The system has an inherent energy reclaim capability allowing simultaneous heating and cooling around a building, with terminal units either taking heat from the water loop or injecting heat into it. Unwanted heat is taken from areas requiring cooling and transferred, via the water loop, to areas requiring heating.

Conversely, areas requiring heating will take heat from the water thus restoring the thermal balance in the loop.

Should the temperature of the water loop rise above or fall below the pre-set band, then heat can either be injected or rejected to bring the temperature back within the pre-set parameters. At any one time only the supplementary heat injector or rejecter will be running, unlike fan coil type systems where a boiler or chiller would operate simultaneously to provide independent heating and cooling.

Experience has proved that for much of the year, the heat pump system can run in a thermal balance without the supplementary heat injector or rejecter being used.

The system can include any number of individual self-contained water source heat pump air-conditioning units connected to the closed water loop system. The unit comprises a hermetically sealed refrigeration circuit with refrigerant-to-air and refrigerant-to-water heat exchangers. The refrigeration circuit is reversed automatically by the user’s thermostat; therefore each heat exchanger acts either as an evaporator or condenser. The airside heat exchanger adds or removes heat from the room by passing air over the indoor coil, whilst the waterside heat exchanger either adds or extracts heat from the water loop.

Many buildings and manufacturing plants contain closed loop water systems, which makes the installation of a reverse cycle water source heat pump system an attractive and economical proposition.

When being employed for full heating purposes the Versatemp system is taking heat from the water loop, which in turn means this heat has to be replaced by turning the boiler on. However, there are other ways of producing replacement heat which are much more energy efficient and cost-effective. Where water is used in a process for cooling, the actual cooling process heats up either water or air and this energy could be injected into the water loop via a plate heat exchanger, rather than rejecting the heat to the outside. As a result, the need to use the boiler for heating in the closed loop is reduced and in some instances eliminated.

In order to cool a room the heat has to be removed and as a result, the temperature in the water loop increases, which means a dry cooler has to be switched on to reduce the temperature and reject this excess heat to ambient. However, in order to minimise the use of a dry cooler and further reduce energy consumption, there will be opportunities to put the rejected heat to alternative uses.

Likewise, with the availability of cold water, the operation of the dry coolers may be reduced. Waste water from industrial processes has to be treated in accordance with environmental agency regulations before it can be disposed of. Once treated, this water becomes a possible energy resource either for cooling or heating, before it is run off to the mains.

The heating and cooling system within a building should, in order to optimise energy usage, be integrated with all services and facilities.

Operating a water loop system can utilise all energy resources and offer benefits over individual non-integrated processes and systems. A water loop system allows the building occupier to install reverse cycle water source heat pump terminal units that both heat and cool, while enabling all heat injection and rejection resources available to be incorporated for optimum plant efficiency. Such is the system’s versatility, it is now possible to incorporate different heating and cooling units, including the large air handling plant used in cinemas or shopping centres, or close control systems used in communications and IT rooms.

Clivet UK

01489 572238