Optimised to take advantage of sub-cooling via vapour injection, Copeland Scroll compressors offer a capacity increase of up to 40% compared to a standard ZF scroll. Robert Kebby, Copeland’s sales director for the UK and Ireland, reviews two studies where this technology has produced energy savings in low-temperature supermarket applications

THE recent enforcement of the Kyoto agreement and the progressive increase in energy prices has reinforced the need to use and design energy efficient refrigeration equipment. Within the UK, Government-implemented via the Carbon Trust, the Enhanced Capital Allowance (ECA) scheme enables businesses to claim 100% first-year capital allowance on their spending on qualifying plant and machinery.

In order to assist manufacturers and end-users in taking the best decision when selecting the most energy efficient compressors, Copeland has worked with various independent consultants to measure the energy consumption of low-temperature packs and complete systems operating in various supermarkets based on different compressor technologies and brands.

Vapour injection for improved efficiencies

Copeland offers a number of energy efficient products. One of the latest examples is the recent introduction of the new Copeland Scroll compressors with vapour-injection for low-temperature applications. Optimised to take advantage of sub-cooling via vapour injection during the compression process enables a capacity increase of up to 40% compared to a standard ZF scroll compressor.

The main benefit of ZF scroll vapour injection compressors is that they were designed to deliver energy efficiencies comparable if not better than Copeland’s Discus semi-hermetic range.

Due to the efficiency improvements, more compact and lighter refrigeration equipment can be built, producing significant cost savings.

Energy field studies

The new Copeland ZF vapour injection scroll compressors have been installed at various supermarket sites for field-testing and for normal operation.

Over a period of a year and a half, one particular site in the UK has been monitored to evaluate its energy performance. These compressors have been running successfully and have delivered a significant energy cost reduction compared to the previous ZF injection scroll low-temperature refrigeration installation.

In south west France, an installation also equipped with the new ZF scroll vapour-injection compressors found the energy efficiency gains were such that the building owner received government funding from the ADEME (Agence De l’Environnement et de la Maitrise de l’Energie), a public office under the French Ministry of Ecology, Industry and Research.

In parallel to these field activities, Copeland has worked with an independent consultant on energy consumption analysis that compares the electricity usage of packs based on these vapour injection scroll compressors with packs built with compressors of other technologies and brands.

The simulation was based on real and existing supermarkets that had been previously monitored by the independent consultant, ensuring that the operating conditions were representative.

Case 1: A 1500m2 supermarket located in Evreux near Paris

A low temperature pack of 17kW nominal capacity operates with fixed condensing pressure at 40°C with a temperature differential of 12K on R404A.

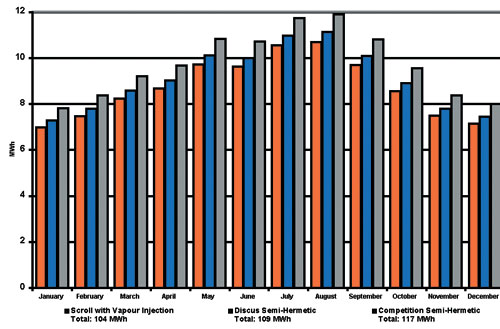

Figure 1 (see page 39) shows the monthly energy consumption of three different packs in MWh.

Under these conditions and including the condenser fans, the vapour-injected pack consumed 104 MWh annually while the Discus semi-hermetic, and the pack based on compressors of other brands, consumed 4% and 12% more respectively.

Case 2: 1500m2 supermarket located in Paris

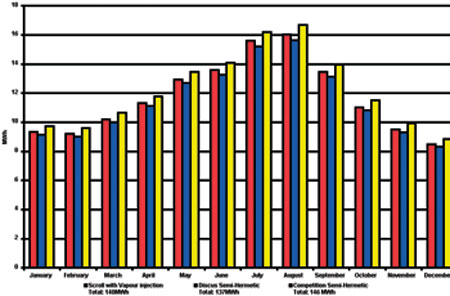

Capacity requirement is 30kW for low temperature application. As in Case 1 the operating conditions are the same except the head pressure is now floated with the ambient.

Under these conditions and including the condenser fans, the Copeland ZF scroll vapour-injected pack consumes 140MWh annually, whilst Discus compressor technology consumed 2% less and the standard semi-hermetic pack of another brand consumed 4% more.

A point that is not reflected in the above but also of significance is the combined effects of sub-cooling and vapour injection technology that make the system capacity output more constant with varying ambient conditions compared with semi-hermetic compressors.

Figure 1: Condensing temperature fixed at 40degress

Figre 2: Floating condensing temperature

Conclusion and summary

From the independent case studies carried out the vapour injected ZF Scroll provides true benefits for the designer and end-user.

From an energy consumption standpoint the overall efficiency of the refrigeration system based on scroll technology is similar to that based on Copeland Discus and better than that of other brands.

The new Copeland ZF48KVE scroll (15hp) with vapour injection provides similar duty, but better efficiency than a 27hp semi-hermetic.

Capital and installation cost savings can be achieved by utilising the additional capacity benefit of either a reduction in the number of compressors used, or by using smaller compressor displacement.

Further costs savings are also possible through the use of smaller suction line sizes.

Pack reliability is improved during winter operation as there is less excess cooling capacity translating into less cycling of the compressors with the associated benefits of improved control, reliability and energy consumption.

Limited cycling leads to a more constant refrigerant flow in the suction line that ensures better oil return to the compressors. Under summer conditions where ambient temperatures are higher, there is less danger of capacity shortfall.

Until the introduction of scroll with vapour technology, no scroll on the market was able to deliver efficiencies for complete systems that were comparable to the Discus.

Driven by both environmental and economical concerns, supermarkets are typically confronted with making difficult decisions between minimising investment costs and reducing operating costs.

The Copeland second generation range of scroll compressors, ZB for medium temperature and ZF with vapour injection for low-temperature applications, now makes this choice easy.

All Copeland ZF Scroll models with vapour injection qualify for the Enhanced Capital Allowance (ECA) tax benefit. For a complete listing of qualified ECA Copeland semi-hermetic or scroll compressors visit www.eca.gov.uk.

Copeland

01635 876161