Why a relief device is required

A refrigerant safety relief device is designed to prevent pressure in a vessel from rising above a safe limit when operating controls fail or when the vessel is exposed to excessive heat.

When a vessel, containing liquid refrigerant, is shut off from other parts of the system a rise in temperature will cause a rise in pressure. If the vessel is completely filled with liquid a small rise in temperature will cause a rapid and excessive rise in pressure due to the expansion of the liquid. If the vessel contains both liquid and vapour, which is normal for refrigerant receivers, the pressure will rise according to the temperature-pressure saturation characteristics of the refrigerant. If the density of the liquid vapour mixture in the vessel exceeds the critical density of the refrigerant, an increase in temperature will cause an increase in the percentage of liquid in the vessel until the vessel is completely filled with liquid. A small increase in temperature beyond this point will result in a rapid and excessive rise in pressure. This condition can occur at temperatures well below the critical temperature of the refrigerant as a result of the exposure of the vessel to excessive heat as in the case of fire.

If pressure builds up high enough to cause the vessel to rupture, large quantities of liquid refrigerant will then be released. This causes a sudden reduction of pressure so that the liquid released is vaporised almost instantly with explosive results. With a suitable relief device installed on the vessel, the refrigerant is released at a controlled rate and a safe pressure is maintained in the vessel.

figure 1

Types of relief devices

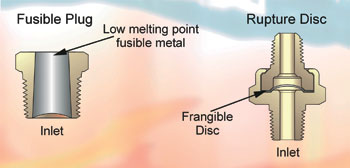

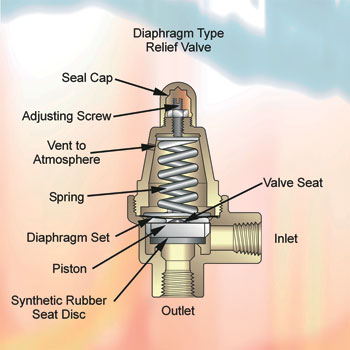

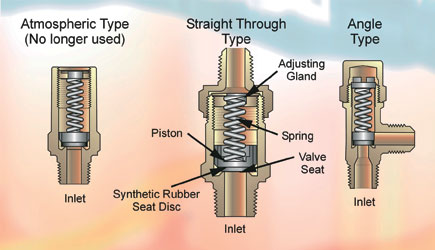

There are three general types of relief devices commonly used, namely: the fusible plug, the rupture member and the pressure relief valve. The fusible plug contains a fusible member which melts at a predetermined temperature corresponding to the safe saturation pressure of the refrigerant. The rupture member contains a frangible disc designed to rupture at a predetermined pressure. The pressure relief valve is a pressure-actuated valve held closed by a spring or other means and designed to automatically relieve at a predetermined pressure.

Relief device selection

Four requirements to select the correct relief device:

1. Type of refrigerant

2. Size of vessel. This determines type of relief device which can be used and the discharge capacity requirement of the relief valve.

3. Design pressure of vessel to be protected. This determines the pressure setting of the relief device.

4. Length of discharge piping required from outlet of the relief valve. Correct size required to prevent back pressure from building up in the discharge piping, and preventing the relief valve from discharging at its rated capacity.

ANSI/ASHRAE 15 code requirements for relief devices Selection of types

1. Pressure vessels with internal gross volume of 3ft3 or less containing liquid refrigerant, which may be shut off by valves from all other parts of a refrigerant system, shall be protected by a pressure-relief device or fusible plug.

2. Pressure vessels of less than 6in inside diameter can be protected by a pressure relief device or a fusible plug from fire or other abnormal conditions.

3. Pressure vessels over 3ft3 but less than 10ft3 internal gross volume may use a single pressure relief valve or rupture member (but not a fusible plug).

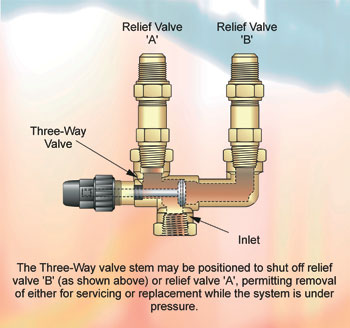

4. Pressure vessels of 10ft3 internal-gross volume or more require a three-way valve and two parallel relief valves. Each relief valve shall have sufficient capacity to protect the vessel, because only one relief valve shall be under system pressure at a time.

5. No stop-valve may be located between the vessel and any relief device except the three-way type with two relief valves permitting only one relief valve to be shut off at a time.

figure 2

Discharge capacity

The ANSI/ASHRAE 15 Code provides a formula for calculating the required discharge capacity of the relief device:

C = fDL

where:

C = Minimum required discharge capacity of the relief device in lbs of air per minute (kg/s)

D = Outside diameter of the vessel in feet (m)

L = Length of the vessel in feet (m)

f = Factor dependent upon type of refrigerant.

When used on the low side of a limited-charge cascade system:

We recommend that the latest edition of ANSI/ASHRAE 15 be consulted for other refrigerants.

This formula was based on a fire condition and developed by assuming a flame temperature to calculate the BTU heat input radiated to the vessel. As pressure rises in the vessel, the discharging relief device acts as an expansion valve to provide a cooling effect. Since the latent heat of vaporisation of the refrigerant is known, it is made equal to the heat input from the fire to determine the amount of refrigerant which must be discharged to maintain uniform temperature and pressure in the vessel.

Since the heat input depends on the size of the vessel exposed to the fire, the diameter D and length L of the vessel become part of the formula. The factor f provides for the difference in latent heats of the various refrigerants and converts the flow of refrigerant to the equivalent flow of air. This permits the rating of relief devices to be expressed in terms of discharge of air in lbs/min regardless of the type of refrigerant used.

For example a pressure vessel 1ft in diameter by 5ft long containing R22 (f = 1.6) would require the relief device to discharge:

1.6 x 1 x 5 = 8lbs of air/min.

For ammonia (f = 0.5) this would amount to only 0.5 x 1 x 5 = 2.5lbs of air/min.

figure 3

This smaller capacity requirement for ammonia is due to its high latent heat of vaporisation with greater cooling effect. Capacities of pressure relief valves are determined by test in accordance with the provisions of the ASME Boiler and Pressure Vessel Code, Section VIII, Division 1 Relief Valves, approved by the National Board of Boiler and Pressure Vessel Inspectors, and are stamped with the code symbol. This symbol consists of the letters “UV” in a clover leaf design with the letters “NB” stamped directly below the symbol. In addition, the pressure setting and capacity are stamped on the relief valve. Capacities of fusible plugs and rupture members, if not stamped by the manufacturer, may be determined by the following code formula:

C = 0.8 P, d2 where

C = rated discharge capacity in lbs of air/min (kg/s)

d = internal diameter of bore of fusible plug or rupture member in inches.

For rupture members: P1 = 1.10 x set pressure PSIG (kPa Gage) + 14.7

For fusible plugs:

P1 = absolute saturation pressure corresponding to the stamped temperature melting point of the fusible plug or the critical pressure of the refrigerant used, whichever is smaller, PSIA (kPa).

The capacity of a relief device will increase proportionately with an increase in pressure setting. Therefore, the capacity stamped on the relief device by the manufacturer is correct only for the pressure setting stamped on the device.

The ANSI/ASHRAE 15 Code formula for determining the required capacity is independent of the pressure setting. To obtain the maximum rated capacity of the relief device, the setting should be as high as the design pressure of the vessel will permit.

Pressure setting

Pressure vessels are normally manufactured to a safety factor of 2.5 to 5 so that the maximum bursting pressure is 2.5 to 5x the rated design working pressure. Importantly, the maximum pressure setting for a relief valve is limited by the design working pressure of the vessel to be protected. The relief device must also have enough discharge capacity to prevent the pressure in the vessel from rising more than 10% above its design pressure. Since the capacity of a relief device is measured at 10% above its stamped setting, the setting cannot exceed the design pressure of the vessel.

To prevent loss of refrigerant through pressure relief devices during normal operating conditions, it is necessary that the relief device setting be substantially higher than the system operating pressure. Unless specified otherwise by local governing codes, the relief valve should be set at a pressure equal to the design working pressure of the vessel as furnished by the manufacturer and stamped on the vessel. For proper functioning of the relief valve, the design pressure of the vessel and corresponding relief valve setting should be at least 25% higher than the normal maximum operating pressure for the refrigerant used.

This factor of safety will provide sufficient spring force on the valve seat to maintain a tight seal and still allow for setting tolerances and other factors which cause settings to vary. Although relief valves are set at the factory within a few pounds of the stamped setting, the variation may be as much as 10% after the relief valves have been stored or placed in service for a period of time.

figure 4

Discharge piping from relief devices

The discharge of toxic refrigerants or large quantities of non-toxic refrigerants through relief devices must be vented to the outside atmosphere or in the case of ammonia into a tank of water. While the relief device is discharging, back pressure will build up in the discharge piping which may prevent the device from performing properly or from discharging its rated capacity. For relief devices with fixed openings, such as fusible plugs and rupture members, this back pressure can build up to approximately 50% of the pressure in the vessel without affecting the capacity of the relief device. This is due to the phenomenon known as “critical flow” through a fixed orifice, whereby a decrease in outlet pressure below 50% of the inlet pressure is not accompanied by an increase in flow.

This condition does not necessarily apply to pressure relief valves since the effective opening through a relief valve depends on both the orifice diameter and the lift of the valve piston, which in turn depends on the pressure difference across the valve. The amount of back pressure permitted without the loss of capacity through a pressure relief valve will vary depending on the design. In most cases it is considerably less than 50% of the inlet pressure.

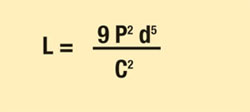

For the purpose of establishing some limit, the ANSI/ASHRAE 15 Code permits a maximum back pressure through the discharge piping of 25% of the inlet pressure while the device is discharging at rated capacity. Knowing the set pressure and capacity of the relief device, the length of discharge piping for each pipe size can be calculated from the code formula:

where

L = Length of discharge pipe or tube in feet (m)

P = 0.25 [(set pressure x 1.1) + 14.7]

d = Internal diameter of pipe or tube in inches (mm)

C = Minimum required discharge capacity in lbs of air per minute (kg/s).

Since this calculation is long and complicated, the results have been published in the form of tables in the code.

It is good safety practice to keep the lengths of discharge piping well within that permitted by the code. This is particularly important for relief valves, since excessive lengths may not only reduce capacity but can cause piston chatter and valve damage while discharging.

Next Month: direct spring load relief valves

With thanks to Mike Creamer of Business Edge who revisits his Masterclass series of articles, updating and adding to the information which proved so useful to readers when the series was first published over ten years ago. In this reincarnation, the series will cover both air conditioning and refrigeration and serve as an on-going source of technical reference for experienced personnel as well as providing a solid educational grounding for newcomers to our industry.