Cooling type dehumidification is generally not suited to this application. For cooling dehumidification to be effective the temperature generally needs to be above 10ºC with 20ºC being the optimum. This does not offer economic solutions for preservation applications.

The UK has over 1,500 museums, historic buildings and private collectors with priceless paintings, manuscripts and artefacts. All suffer the effects of excessive moisture. If these are left in an unprotected environment they would deteriorate eventually to the point of destruction.

Most industries require some form of storage facility and failure to protect raw materials, finished goods and buildings from the effects of excessive moisture costs British Industry millions of pounds every year.

Unfortunately the UK has one of the wettest climates in the northern hemisphere and high humidity constitutes a continued and unseen threat to profits and our national heritage.

The level of relative humidity in the air within a display or storage environment is critical to the suitability of that environment to contain the objects that would otherwise perish or corrode. Water retentive materials such as paper, textiles and wood absorb moisture and create a suitable environment for bacterial, mould and fungal growth. By removing the moisture from the environment the damaging effects can be eliminated.

Metals

Ferrous, non ferrous metal and alloys corrode rapidly in the presence of water vapour and the rate of corrosion is further accelerated by natural or industrial pollutants in the air. Bronze for example can develop the phenomenon known as bronze disease breaking into active corrosion if the relative humidity is too high. Corrosive activity is significantly reduced at RH levels below 60%.

Archives

The long term storage of paper and film needs very special conditions. For example old flammable nitrate film shrinks and decomposes with age and needs to be carefully copied onto modern safety film if it is to be preserved.

Humidity is the key factor affecting acetate film degeneration. The optimum conditions required are 30% relative humidity with temperatures ranging from 3ºC to 20ºC if the safety of the film is to be guaranteed.

Fig 1: metal corrosion

Corrosion

All materials corrode, which is to say every substance eventually changes from one form to another through chemical reactions. Many of these reactions, especially those which depend on oxygen, are catalysed and accelerated by moisture.

While ferrous metals are well known for their corrosion in the presence of moisture, less well known is the fact that glass corrodes and cracks at a rate which varies according to the moisture on its surface. Pure crystals like sodium iodine and lithium fluoride also corrode, forming oxides and hydroxides in proportion to the moisture in the air.

Modern society depends more and more on computers, telecommunication equipment and lightweight composite materials using high energy batteries. While these are less subject to external gross rusting, they are very sensitive to microscopic corrosion. The tiny electronic circuits create disproportionately large problems if exposed to small amounts of corrosion.

Electronics protection

Computers and other electronic equipment use small voltages and low currents to perform their functions. When minute layers of corrosion build up on circuit surfaces they increase electrical resistance and decrease capacitance which can seriously affect calibration and performance.

Lithium battery production

Lithium, plutonium and other high energy metals are hazardous because they ignite when atmospheric water vapour makes them corrode. Desiccant dehumidifiers control large production areas at moisture levels below 1% relative humidity which makes it possible to work these materials safely. This has made large scale production of lithium batteries economically viable. Without desiccant dehumidification the lithium battery would still be an expensive special purpose curiosity.

Condensation

When cold surfaces are surrounded by moist air, water vapour will condense on the surface. Condensation can lead to a surprising number of problems. For instance, customers in a supermarket may not be able to see frozen products in a refrigerated display case with a glass door. It may be obscured by condensation or frost.

Condensation can also form on hidden aircraft structural members as the plane descends from the cold upper atmosphere into moist environments. This has had disastrous results.

Often, condensation control creates economic opportunities rather than simply preventing a problem. A classic example being chilled rollers used in many industrial processes. By surrounding the rollers with dry air the coolant temperature can be optimised without the usual condensation forming. This provides the economic opportunity for increased production and reduced spoilage.

Other areas where condensation can be a problem include ice rinks, swimming pools and water treatment plants.

In an ice rink, the build up of condensation created by spectators is exacerbated by moist air from outside the building. Moisture condenses on the ice surface and spoils the skating conditions. With RH often at 90% to 100%, there is potential moisture damage throughout the entire building.

Desiccant dehumidifiers can prevent this and, in so doing, save thousands of pounds by removing this massive latent load from the refrigeration plant.

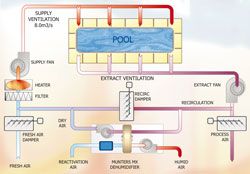

In even a medium-size swimming pool, evaporation from the warm surface of the pool can amount to more than a ton of water per day. Unless this water vapour is efficiently removed condensation will occur and damage the fabric of the building. High levels of moisture in the pool hall air will also make conditions uncomfortable for bathers and staff. Both will have serious financial consequences. To avoid deterioration of the building fabric and meet the comfort conditions, the relative humidity has to be kept under 65%.

In water treatment plants, the ground water and lake temperatures are often much lower than atmospheric dewpoint. This results in condensation on the outside of the pipes, valves and control in the plant rooms. This causes corrosion, mould and fungus growth.

Cold storage

Moist air entering a cold store condenses and then freezes to form ice when it comes into contact with cold surfaces such as floors, walls and evaporator coils. If the cold store has a loading dock it may remain as condensate but will result in wet floors and surfaces. This is potentially dangerous for workers.

The loss of cooling capacity is another concern. Build up of ice on evaporators greatly reduces the efficiency of the cooling plant and cold store temperature increase is a constant worry to cold store managers.

Design considerations

In designing dehumidification installations there are few tasks as important as quantifying the moisture loads to be removed. Without a clear understanding of the dimension of the loads, their frequency and source, it is impossible to design a system to remove them.

While the task is essential, moisture load calculation has historically been a somewhat controversial and personal procedure. That may seem odd given the well defined tables and graphs developed to assist the engineer but the uncomfortable fact remains that two equally qualified individuals may arrive at different total moisture loads for the same space.

Fig2: Swimming pool dehumidification

Regardless, the engineer must make many assumptions and in the final analysis, the moisture load sheet represents a common agreement between equipment manufacturer, system designer and the owner of the installation. It defines the assumptions that form the foundation of the system design.

Key considerations

· External ambient conditions - maximum summer and minimum winter conditions must be considered. Advice is available from ASHRAE for standard design data.

· Internal conditions - the required conditions for the process. Each application will have a requirement relative to a particular situation. The condition must be specified in absolute terms (g/kg) before the calculation can proceed.

· Moisture load sources

Once the engineer has selected the inside and outside design conditions, the moisture load calculation for each element can proceed.

Moisture load sources

There are seven principle sources of moisture:

· Permeation through walls, floors and ceilings

· Evaporation from persons' clothes, breath and perspiration

· Desorption from moist products, including packaging materials

· Evaporation from wet surfaces or open tanks

· Generation from combustion

· Air infiltration through leaks, holes and door openings

· Fresh air ventilation from outside of the conditioned space

Each moisture source has to be carefully accounted for and either added to the total or discounted. Therefore, it takes an experienced application engineer to accurately calculate this for process work but preservation applications are relatively simple.

Generally, the principle load for preservation type applications is the infiltration rate. This is based on air change rates and informed engineers can reasonably establish this.

Case study

A warehouse storing cardboard packaging is suffering from dampness which softens the packaging and creates difficulties for the packaging machinery. The moisture is effecting the visual appearance of the packed product and the end user is returning product to the manufacturer.

The engineer establishes that the recommended storage condition for cardboard is 50% RH. Temperature however, is not important and does not need to be considered.

Moisture load from infiltration:

Warehouse volume 2000m3

Air change rate 0.5/hr

Summer worst condition 28ºC , 12g/kg (50% rh)

Required conditions 50% R/H at ambient

At 28ºC the space is safe but as the temperature drops the relative humidity increases. To maintain the RH we must remove moisture or maintain the temperature.

The actual load is calculated using the dewpoint temperature for 12g/kg and calculating 50% RH against that value (6g/kg) NB: 1.2 is standard value in kg/m3 for the air density.

Fig3: Archive protection

The engineer would now contact an equipment manufacturer for price estimates for a dehumidifier to cope with a load of 7.2kg/h at the design condition.

This principle can be applied to most preservation type applications but the engineer should be aware that other factors could influence the final moisture load. This calculation is very simplistic and should be used for guidance only.

The alternative to removing the moisture is to maintain the temperature. Heating storage warehouses to maintain conditions is still recommended by some consultants. The graph illustrates the cost differentials between the two methods.

Fig: 4 Graph: operating costs

If heating is used the air temperature has to be maintained throughout the year and not just over the winter. Costs to Industry for heating storage areas is huge and a survey of 300,000 buildings concluded potential savings of £114m/annum was possible.

Understanding the principles of dehumidification is a specialist subject but the basics can be reasonably applied by most engineers familiar with air conditioning principles.

Use of the Mollier diagram or psychrometric chart is a great help and familiarisation with this tool is highly recommended to anyone who is looking at dehumidification as a solution to any related moisture problem.

With thanks to Mike Creamer of Business Edge who revisits his Masterclass series of articles, updating and adding to the information which proved so useful to readers when the series was first published over ten years ago. In this reincarnation, the series will cover both air conditioning and refrigeration and serve as an on-going source of technical reference for experienced personnel as well as providing a solid educational grounding for newcomers to our industry.